Model 78 - QC Mark

Application Details

Application Description

Enhancing Quality Control with Mite-E-Mark

A manufacturer faced significant challenges in tracking production part quality during a critical testing procedure. When defects arose, they struggled to determine which parts had passed through the test stand, making it difficult to trace issues back to a specific production run. This led to costly delays and inefficiencies in their quality control process.

The Challenge

They considered laser marking and dot-peen marking, but both solutions were too costly and complex for their needs. Additionally, their testing station had limited space, making integration of a marking system difficult.

The Solution: Date Coding with Columbia Marking Tools

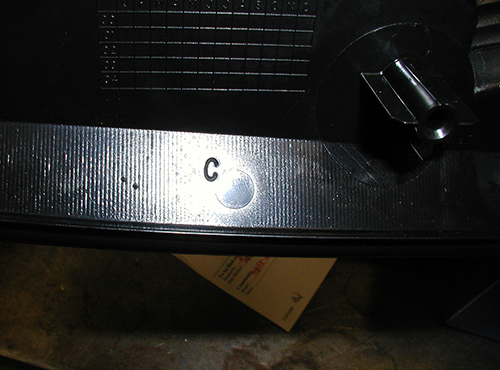

Columbia Marking Tools provided the Mite-E-Mark, an air impact marker designed for compact, cost-effective, and reliable part identification. This solution allowed them to:

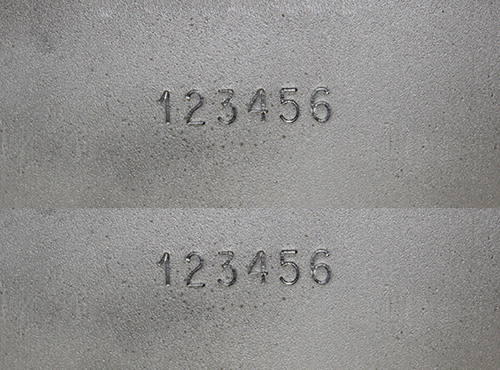

- Permanently mark a QC acceptance mark on all parts passing the test

- Ensure clear identification for tracking and quality controls

- Avoid the high costs and maintenance of laser marking

- Integrate easily into their workflow

As a result, the manufacturer gained full traceability of their production process without exceeding their budget or requiring complex equipment.