CM9 1/2" Round Inserts

CM9 Round Inserts

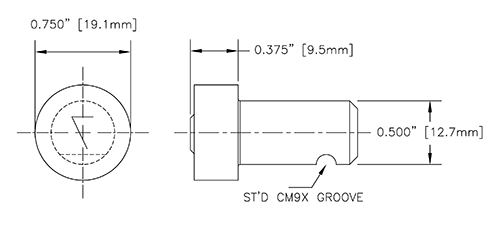

The CM9 round insert are the most widely used inserts of the CMT product liner. These 1/2" diameter inserts are made in the USA from qulity tool steel.

Tooling that uses the CM9 round inserts.

- Standard =

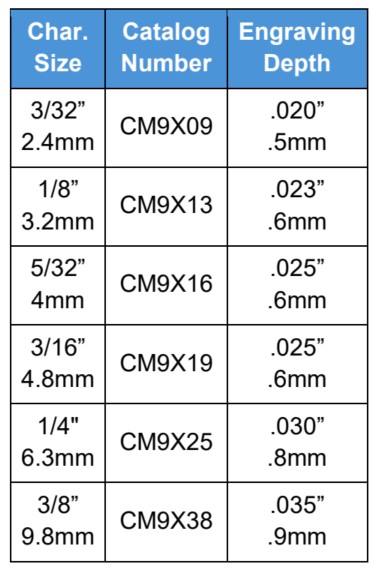

- CM9X inserts are used in the Model 98/298/451/751/851 - "OB" rod

- Wide Head =

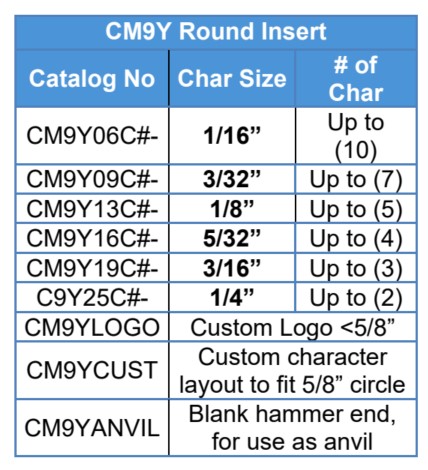

- CM9Y inserts are used in the Model 98/298 - "OY" rod

The CM – round inserts are used for indention marking and are held in the stamp recess/holder with spring clip or set screw. Round inserts are frequently used to provide station ID and part tracking QC marks. Round inserts always center the mark in the tool holder.

Columbia Marking Tools CM9 1/2" Round Inserts

Comprehensive guide for round inserts.

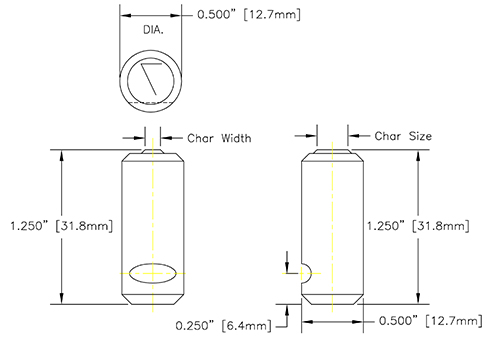

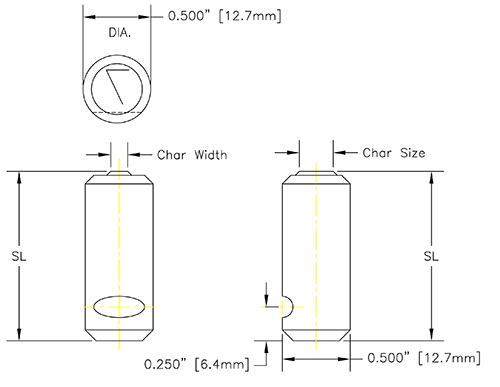

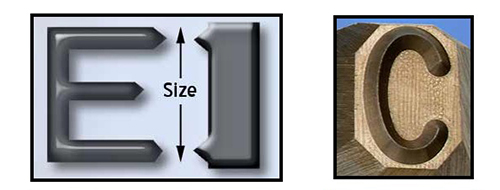

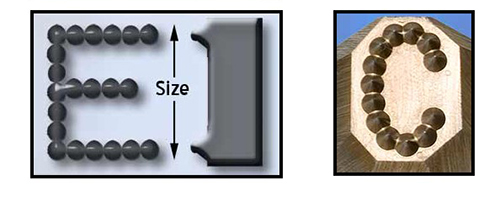

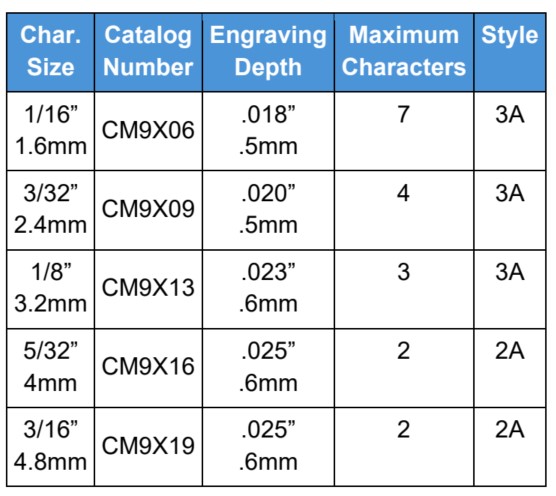

Char Size – Measured from the top of the character.

Char Width – All sizes are Style 3A, width is 60% of the character size.

Tolerance - +.000”/-.001” on all dimensions.

Char Size – Measured from the top of the character.

Char Width – All sizes are Style 3A, width is 60% of the character size.

Tolerance - +.000”/-.001” on all dimensions.

Standard CM9X Round Inserts are engraved as sharp face characters. This type of face style is engraved with a sharp edge. A sharp face tool penetrates more easily than other styles.

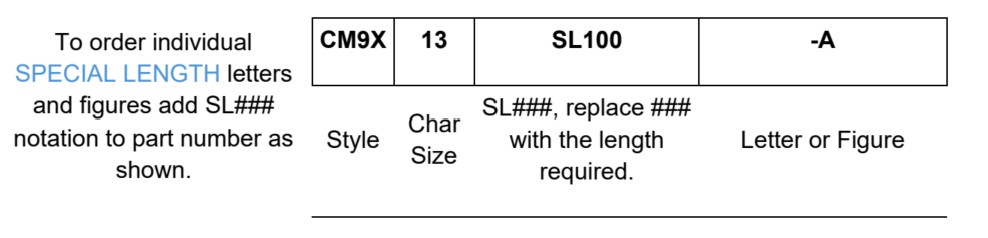

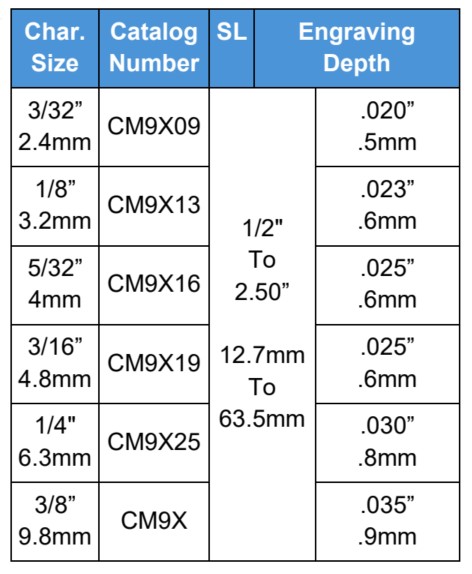

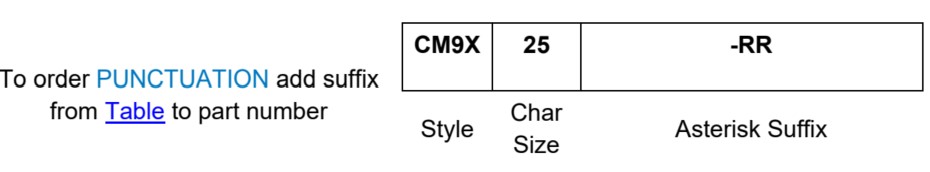

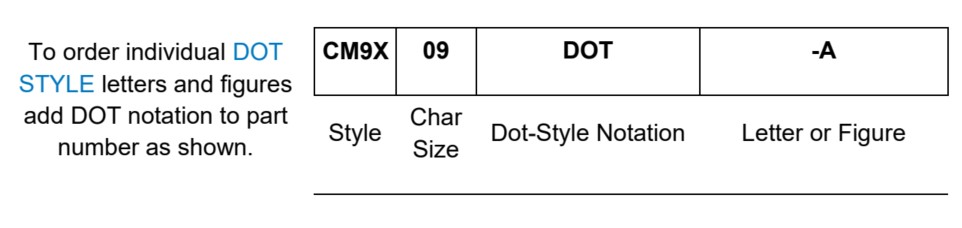

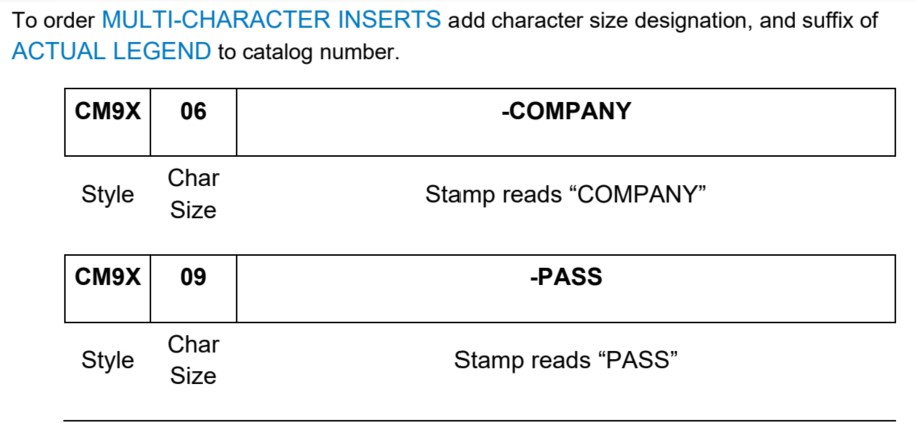

Build Catalog Number as shown:

Dot Style Characters are engraved with a series of conical dots for the lowest possible stress when marking. Recommended for high pressure fittings, aircraft, and other parts where sharp tools might disrupt the molecular structure of the metal.

Multi-character round inserts are great for static marking lengends and QC marks.

Important Notes

- The "OY" Rod has a machine from face to support the wide head and insure durability.

- The CM9Y is a great insert for Muti-Line legends. Example: Line #1 "MADE IN" Line #2 "USA"

- The CM9Y can be purchased as an “Anvil”. The blunt force can be used for non-marking assembly operations, or to provide the force needed to mark characters sitting on the reverse side of the part from the marker.

Char Size – Measured from the top of the character.

Tolerance - +.000”/-.001” on all dimensions.