Model 98 - 8 Ton Single Acting

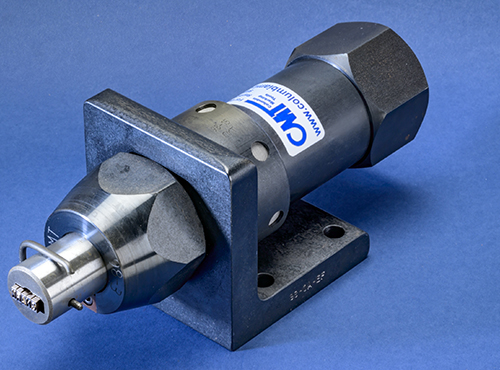

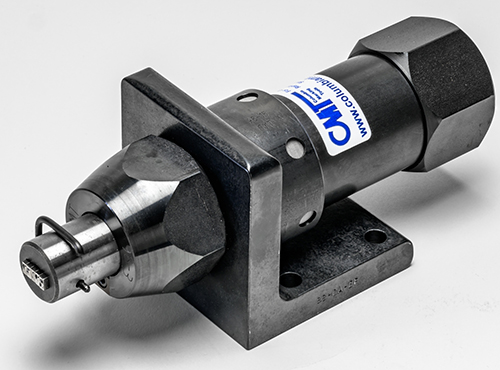

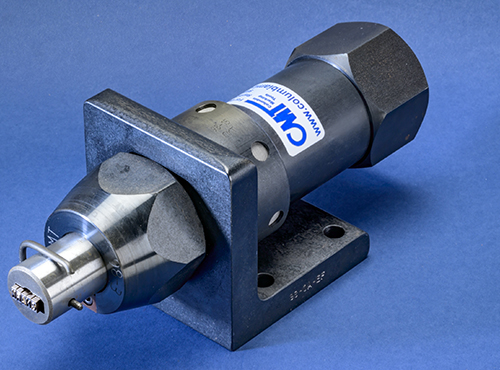

CMT Model 98 - Single acting 8 ton air impact marker

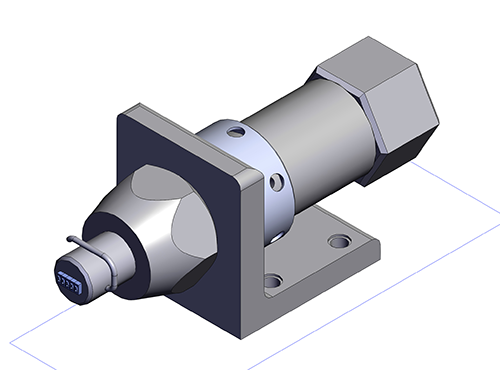

The Model 98 is a 8-ton single-acting air impact marker designed for integration into manually operated stations. Its compact and industrial design allows for easy placement in a production cell, making it ideal for date coding or part numbering on industrial parts. This reliable system ensures consistent marking performance, enhancing productivity in manufacturing environments.

Is an Air Impact Marker the Same as an Air Cylinder?

No. Despite both using compressed air, they operate on different principles:

- Air Cylinder: Generates linear motion through air pressure and piston area, calculated by the equation F = P × A. For example, the Model 98 cylinder produces 165 lbs of force at 80 psi.

- Air Impact MarkerOperates on the principle of F = MA (Force = Mass × Acceleration). The acceleration of the rod/stamp holder generates high force output, resulting in 16,000 lbs of impact force with the same 80 psi.

Force Comparison- Model 98

- Bore Size: 1.625"

- Air cylinder Force: 165 lbs

- Air Impact Force: 16,000 lbs

CMT Model 98 8 Ton Air Impact Marker

Comprehensive Operation Guide with ordering and maintenance guidelines.

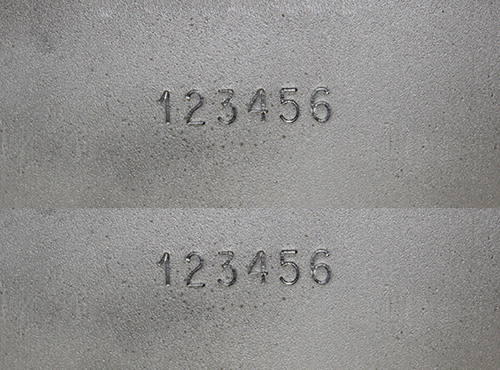

Marking Examples

Product Information

The Columbia Model 98 is an impact marking cylinder designed for robust and reliable performance. Here are the key features:

- Design: The model is built as a rugged pneumatic tool with various pockets at the rod end for stamp character inserts, allowing it to deliver powerful impact blows.

- Impact Force: Capable of delivering a substantial impact force of up to 8 tons at 80 psi (pounds per square inch). This makes it suitable for various industrial marking applications.

- Shock Absorption: The cylinder is equipped with patented shock-absorbing bumpers at both ends of the stroke. This feature is designed to prevent damage to the marker during the forward stroke and reduce shock during the return stroke.

- Dependability: The Model 98 is highlighted as a dependable marker, offering reliable performance while maintaining a low investment cost.

- Rod Action: The rod features a spring return action, enhancing efficiency and contributing to a quick return stroke.

- Pressure Venting Sytem: An efficient pressure venting system is incorporated, allowing for an instantaneous return stroke. This feature contributes to the overall efficiency of the marking process.

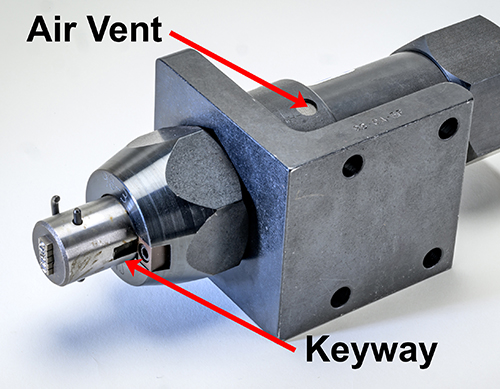

- Keyed Non-Rotating Rod: The rod is designed as keyed and non-rotating, ensuring precision and accuracy in the marking process.

- Stroke Length: The model offers 2.5 inches of stroke, providing versatility for different marking requirements.

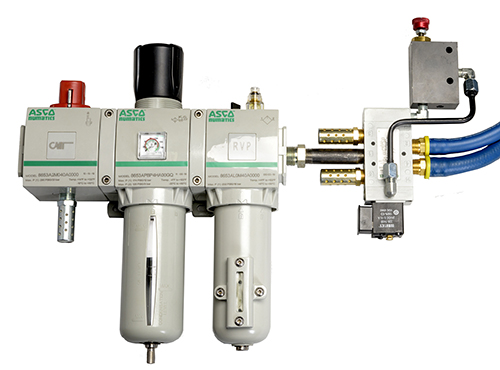

- Lubricated Air Requirement: The standard system still requires lubricated air for optimal performance. This ensures smooth operation and helps maintain the longevity of the components by reducing friction and wear.

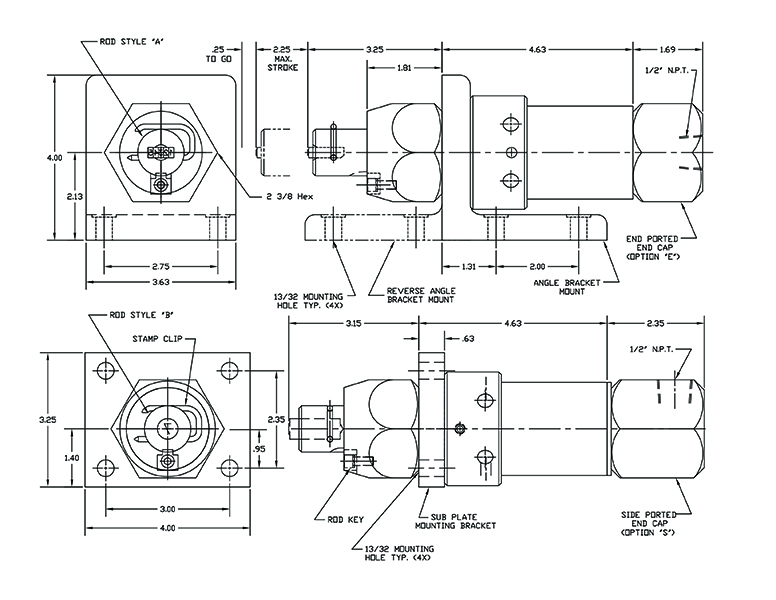

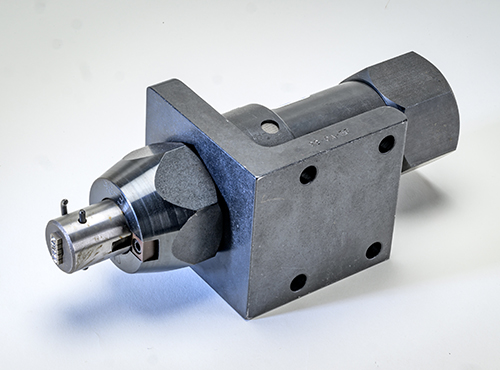

Shown with most popular configuration; standard angle bracket mount, round stamp holder (Style A), and end ported.

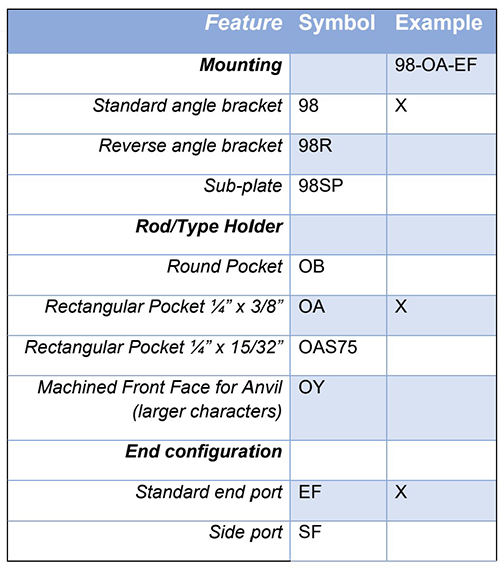

- Mounting Styles =

- Standard angle bracket

- Reverse angle bracket.

- Sub-plate mount

- Rod Styles =

- Muti-character OA for CMG groove type

- Muti-character OAS75 for CMG groove type

- Single character OB for CM9X round insert.

- Single character OY for CM9Y round insert..

- Air Port Locations =

- Standard end port

- Side port for installation with restricted space

- Stamp Capacities Rod Style “B” =

- (1) Pc CM9X round insert can mark up to a 1/4” character.

- Stamp Capacities Rod Style “A” =

- (10) Pc’s 1/16” Char. of CMG06 Stamp Inserts. (5) Pc’s 1/8” Char. of CMG13 Stamp Inserts

- Stamp Capacities Rod Style “AS75” =

- (12) Pc’s 1/16” Char. of CMG06 Stamp Inserts. (6) Pc’s 1/8” Char. of CMG13 Stamp Inserts

- Stamp Capacities Rod Style “Y” =

- (1) Pc CM9Y round insert can mark larger character and longer marking legends. Warning unit may not have force required to indent larger character and legends depending on the material being marked. Please review parameters with marking pressure chart.

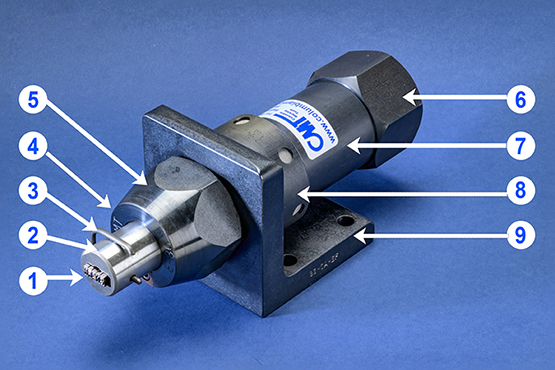

Model 98 rod style A

- Stamp - wearable part

- Rod/Stamp Holder

- Spring Clip - Retaining clip

- Keyway - maintains orientation of stamp(s)

- Front Nut - do not remove, will void warranty

- Rear end cap - remove for seal replacement

- Sleeve

- Muffler assembly - protect system from particulate

- Mounting Bracket - do not remove, will void warranty

Technical Details

Select options from the chart to build the complete part number.

Selections: