CMT Marking Machines

CMT: Comprehensive Industrial Marking Solutions

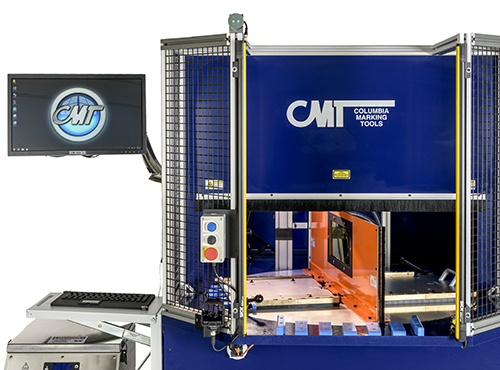

Columbia Marking Tools (CMT) offers a complete line of industrial marking machines, including air impact presses, roll marking machines, dot-peen marking machines, scribe marking machines, and Eclipse laser marking systems. Every machine is proudly manufactured in the USA and built for durability, precision, and reliability in part marking and traceability applications.

CMT’s marking systems can be fully configured to meet customer-specific requirements, ensuring the perfect solution for any industrial application. Whether you need a standalone machine or a fully integrated marking system, CMT delivers high-performance solutions tailored to your production needs.

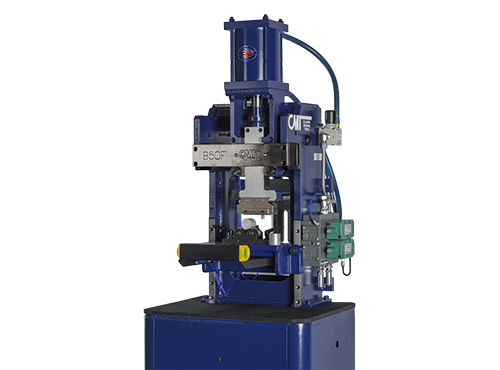

Air Impact Marker Presses: A Turnkey Solution for Precision Marking

Air impact marker presses are the go-to solution for industrial marking applications, offering precision, efficiency, and versatility. Designed as a turnkey system, these presses seamlessly integrate into various production environments, whether manually operated or robotically loaded. Their quick installation and user-friendly setup make them ideal for applications such as part numbering, branding, and quality control.

Built for durability and reliability, air impact markers ensure consistent, high-quality imprints on a variety of materials, from metals to plastics. By streamlining the marking process, these systems help manufacturers maintain compliance, improve traceability, and enhance operational efficiency. Whether you're looking to optimize a production line or improve product identification, air impact marker presses provide a robust and cost-effective solution.

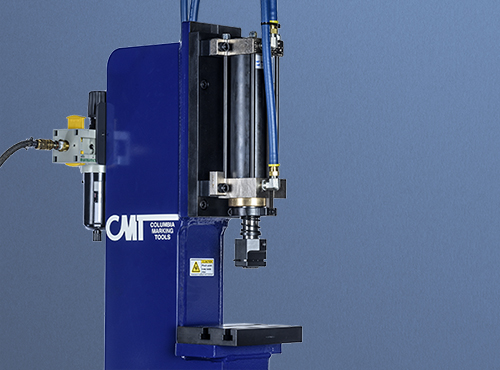

Roll Marking: A Cost-Effective Solution for Precision Marking

Roll marking is a highly efficient and economical marking method that "rolls" the imprint onto a part, reducing the need for high tonnage presses. This technique is particularly beneficial for applications where excessive force would be costly or could damage delicate components. By applying characters one at a time, roll marking minimizes required force, extends equipment longevity, and lowers overall machinery costs.

This method is versatile, accommodating both round parts with flat dies and flat parts with round dies, making it suitable for a variety of shapes and surfaces. Columbia Marking Tools (CMT) offers a wide range of roll marking solutions, including air, hydraulic, and servo-powered rams. From basic manual systems to fully automated roll marking machines designed for high-volume industrial applications, CMT provides reliable, high-quality marking solutions tailored to your production needs.

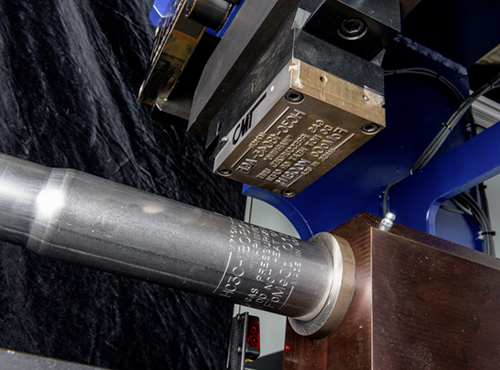

Dot-Peen Marking Machines: Precision, Durability, and Versatility

Industrial marking and part traceability rely on various marking technologies, with dot-peen marking being one of the most widely used methods. This process utilizes a fast-actuating stylus “hammer” controlled by CNC-driven 2+ axes. As the hammer indents the material with a series of small dimples, the motorized axes precisely guide it to form characters, logos, or codes.

With over 40 years of industry use, dot-peen marking has evolved into a diverse field with multiple manufacturers offering a variety of systems and configurations. Key factors to consider when selecting a dot-peen system include motor type and size, pin design, axis configuration, communication capabilities, and software controls. Reliability and cost must also be balanced based on specific application requirements.

Columbia Marking Tools’ I-Mark line combines industrial-grade durability with cutting-edge technology. Available as benchtop units or fully integrated systems for automated production, I-Mark solutions offer unmatched performance and adaptability for modern manufacturing environments.

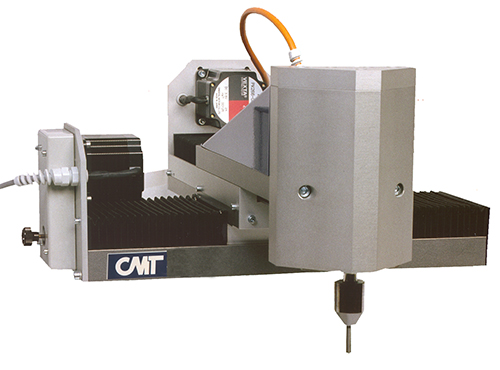

I-Mark Silent Scribe: High-Speed, Programmable Marking for Precision Traceability

Columbia Marking Tools' I-Mark Silent Scribe system delivers precise, low-noise marking with advanced ball screw drive technology. Available with stepper drives for speeds of up to 5 characters per second or high-speed servo drives reaching 8 characters per second, these systems provide flexibility to meet various production demands.

All I-Mark machines support UID/2D Square-Dot® marking, ensuring compliance with industry traceability standards. Designed for durability and efficiency, these industrial programmable marking systems are essential for manufacturing environments requiring date codes, serial numbers, and part numbers for part tracking and traceability.

Whether for standalone use or full automation integration, the I-Mark Silent Scribe offers a reliable and high-performance solution for permanent marking applications.

Laser Marking: Flexible, Efficient, and Built to Last

Laser marking offers unmatched flexibility, high efficiency, and durability for a wide range of applications. Columbia Marking Tools (CMT) provides advanced laser solutions designed for long-lasting, maintenance-free performance. Whether you need compact systems for small-part marking or large-scale solutions for oversized components, CMT offers a variety of configurations to fit your needs.

From manually loaded workstations to fully automated, robotically integrated systems, our laser marking solutions deliver precision, consistency, and reliability—ensuring high-quality marks with minimal downtime. Whatever your production requirements, CMT has the right laser marking system to enhance your operation.