Hot Stamping Units and Presses

CMT Hot Stamping Units and Presses

Technical guide to Plastic marking.

Hot Stamping Process

There are many different hot stamping methods. Hot stamping is used for everything from decorative marking to assembly operations on plastic parts. The hot stamping process uses a heated die to be applied to a plastic foil or plastic material. Columbia Marking Tools offers a compact hot stamping solution for:

The CMT hot stamping systems are available as either units or complete stations. The 900 series of hot stamping units are perfect for integration in automation. These industrial and compact units are designed for high volume production. The machines can be manually operated or loaded by a pick-n-place or robot.

Variables for Hot Stamping

Three variables for the process of hot stamping:

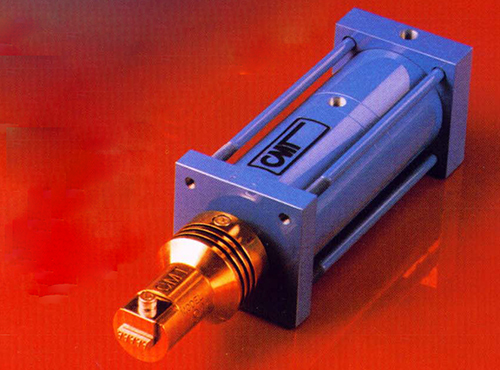

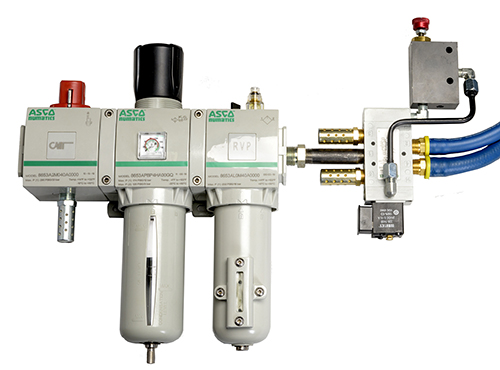

- Pressure Control =

- Pressure is generated by a double-acting air cylinder that is regulated by an air pressure regulator, ensuring consistent application of force.Normal operating pressures for the CMT hot stamping units are from 20psi [1.4 bar] to 80 psi [5.5 bar]

- Heat Distribution =

- Heat is supplied to the die using high-density cartridge heaters. These heaters guarantee uniform heat distribution and are controlled either by a basic temperature switch or a J wire thermocouple. Normal operating temperatures for CMT hot stamping units are from 160° F [71° C] to 240° F [115° C]

- Dwell Time =

- The dwell time, or the period the heated die remains in contact with the workpiece, is regulated by a solenoid valve, ensuring precise timing for optimal results. Normal dwell times for CMT hot stamping applications range from fractions of a second to 5 seconds.

Hot Stamping Applications

There are two basic styles of CMT hot stamping marks. Hot stamping can create both bold, eye-catching marks and more subtle, understated impressions, depending on whether a contrasting foil is used.

- Marking with contrasting foil =

- This method produces bold, highly visible marks, making it ideal for applications such as logos or part numbers where readability and prominence are key.

- Marking without contrasting foil =

- In this approach, the stamp creates a subtle impression without adding color, perfect for uses like quality control (QC) marks, part tracking, and date codes—areas where the mark needs to be present but not visually dominant.

This versatility makes hot stamping a valuable technique in manufacturing, offering both strong branding and essential, discreet identification.

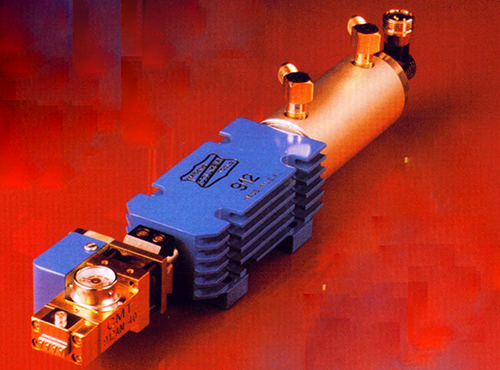

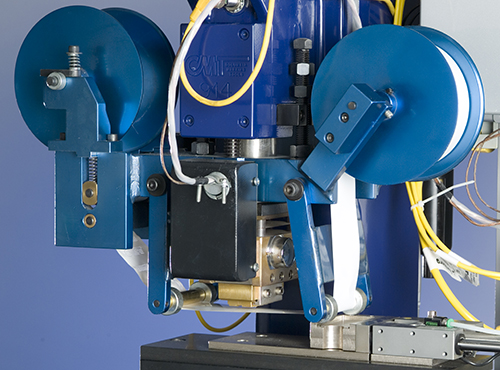

Hot Stamping Unit Medium Model 912

The Model 912 is Columbia Marking Tools’ most popular and versatile hot stamping unit, celebrated for its power and adaptability. Engineered to meet a wide range of traceability needs, it delivers exceptional performance across diverse marking applications. With its combination of strength and flexibility, the Model 912 is the go-to solution for manufacturers requiring reliable and consistent marking for part traceability.

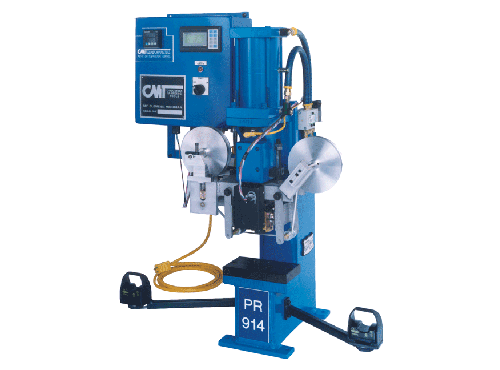

Hot Stamping Presses

Available in 1/2 ton or 1-ton configurations, the Columbia Marking Tools hot stamping presses are designed for durability and efficiency, built on a robust industrial-grade frame and fully assembled for immediate use. These presses come equipped with all necessary connections for seamless integration into your production line.