CMT Roll Marking Tooling

Roll Marking Tooling

Roll marking tooling differs when marking flat versus round parts.

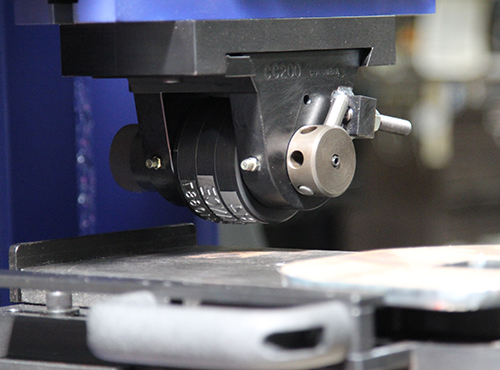

- For flat parts, the die or tooling is round and rolls across the stationary part to create the mark.

- For round parts, the die or holder remains flat while the round part rotates or rolls during the marking process.

Columbia Marking Tools offer a wide selection of options for all roll marking applications. Confusing?

Roll Marking Tooling For Marking Flats

Complete guides and technical data sheet

Roll marking: Tooling for flats

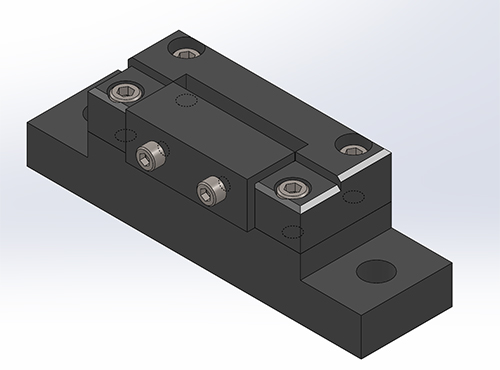

For roll marking on flat parts each application requires 3 components.

- 1. Roll Carriage =

- Mechanism to allow round marking tooling to rotate.

- 2. Round marking tooling =

- Solid Roll die for static marking or roll type holder for variable marking.

- 3. Fixture =

- Solid part backup and part holding detail to secure work piece in place during marking operation.

Each roll marking machine has a different type of configuration with these (3) basc elements.

Round Tooling: A Selection of styles

For roll marking on flat parts Columbia Marking Tools offers a selection of different options.

- Roll Die =

- Solid round tooling with static marking legend. Perfect tooling for logos and part numbers.

- Single Line Roll Type holder =

- Interchangeable type allows for flexible marking legend. This tooling is the right choice for date codes and heat codes

- Multi-line Roll Type Holder =

- The Multi-line holder can have many lines of flexible information. However, the roll marking machine must have enough force to mark all the lines at once.

Many roll marking applications require a roll carrigae to facilitae the roll die or holder to roll across the part during the marking proces.

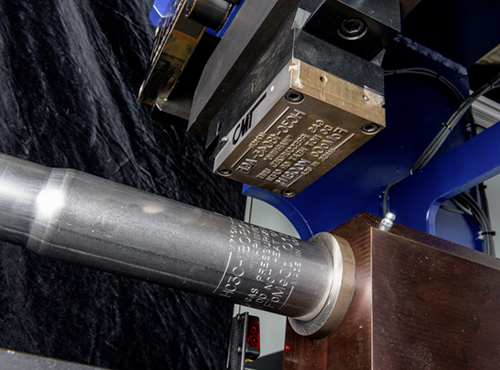

Roll Marking On Rounds

Roll Marking Tooling For Marking Rounds

Easy selection guide for roll cradles and flat holders

Roll marking: Tooling for rounds

For roll marking on round parts each application requires 2 components.

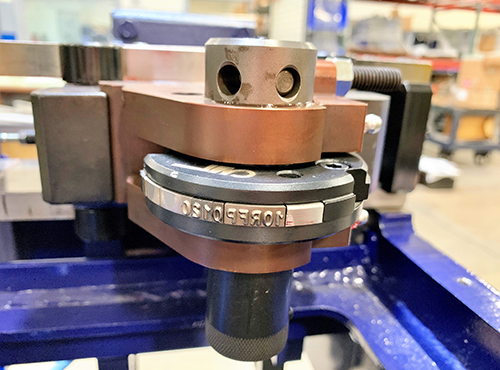

- 1. Flat die/holder =

- Solid die or holder for flat type.

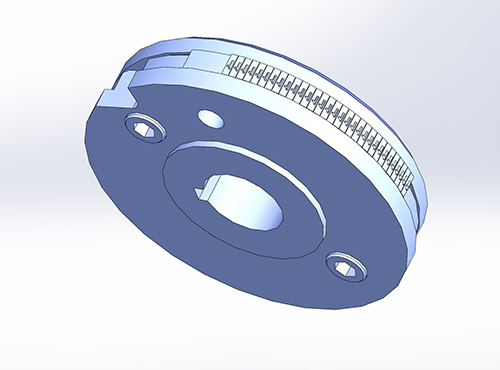

- 2. Roll cradle =

- Rotating fixture or internal mandrel for allow part to rotate during the marking proces.

Each roll marking machine has a different type of configuration with these (2) basc elements.

Round Tooling: A Selection of styles

For roll marking on flat parts Columbia Marking Tools offers a selection of different options.

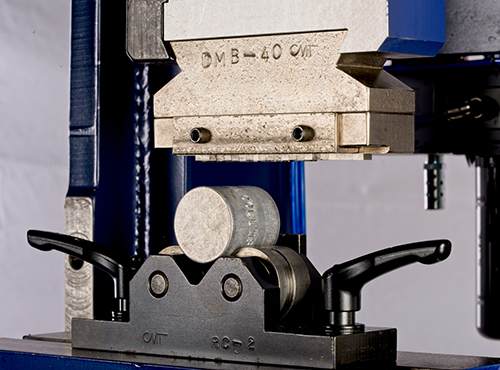

- Dovetail Holder =

- The easy to set dovtail is a CMT classic tooling design to assure fast changeover of markig legends.

- T-Slot Holder =

- The T-Slot holder is a standard press design holder and may be used in both roll marking and press arking applications.

Both of the above designs use the CMS Columbia Marking T0ols Step type.

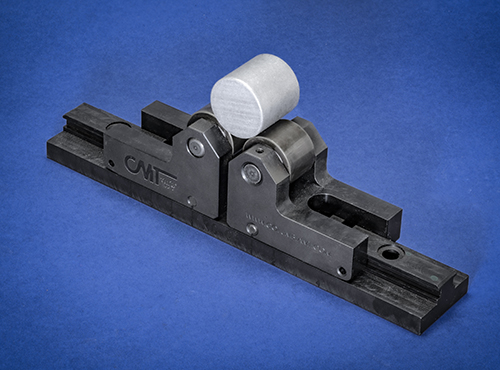

- Roll Cradle =

- The roll cradle offers the best methos to assure solid rotation of the part during the marking process.