Slide-A-Mark Press

Slide-A-Mark Robotic Marking Station

The Slide-A-Mark press offers a turnkey solution featuring Columbia Marking Tools' unique telescoping air impact marker. This innovative marking unit is integrated with a C-frame and control system, providing a compact and efficient marking solution.

The press can be loaded manually or through robotic automation, making it adaptable to a variety of production setups. Designed for high-volume marking applications, the Slide-A-Mark press excels in applying part numbers, serial numbers, quality control (QC) marks, and more with precision and reliability.

Slide-A-Mark Press

Ready to run in Industrial High Production

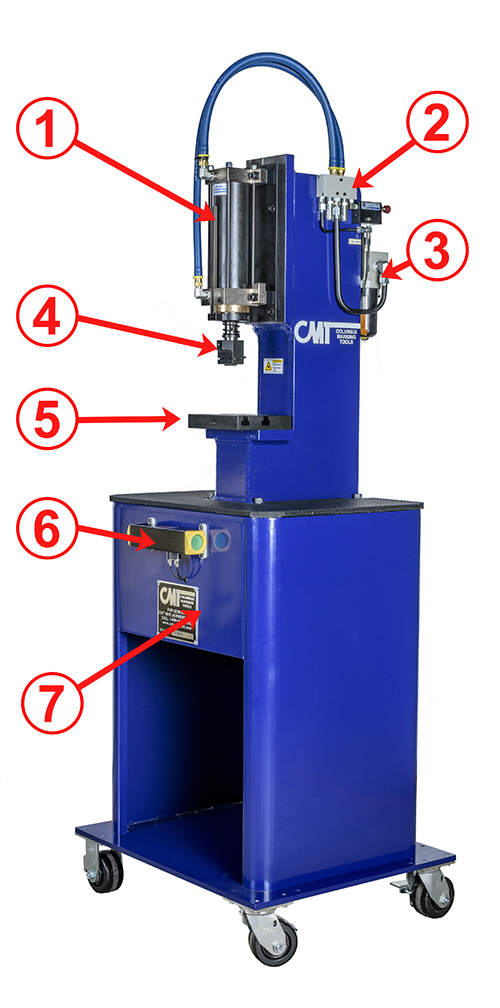

Station Components

The PR751/PR851 Slide-A-Mark Robotic marking station is composed of the following key components:

- Air-Powered Ram

- Provides the driving force for marking operations.

- Controls

- Includes operator interfaces for starting and managing the marking cycle.

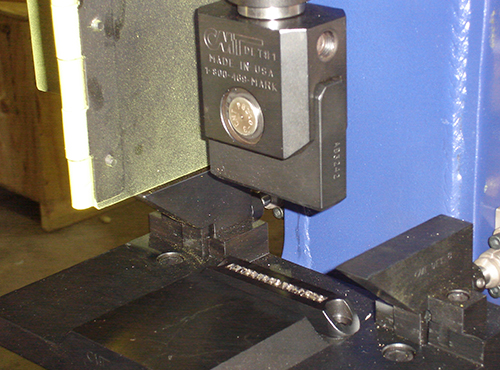

- Stamp Holder and Stamps

- Designed to securely hold and position the marking stamps. Upgrades include numbering heads for serial numbering.

- Frame Options

- Mounted on either a bench frame or a floor-style base, depending on application requirements.

- Safety

- OSHA required palm buttons or guarding with a part present cycle start.

The marker is available in various standard rod styles to suit different marking needs. Additionally, numbering heads can be mounted on the PR751 for specialized numbering applications. A system of air valve devices precisely controls the impact to ensure consistent and accurate marking results.

Marking Sequence

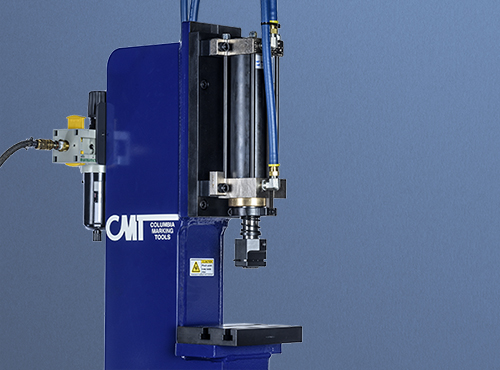

This unique marking system operates based on a two-stage impact mechanism developed and patented by CMT. The process follows these steps:

- Approach: The marker moves toward the workpiece.

- Squeeze: The marker applies a controlled squeeze to the workpiece to stabilize it.

- Mark: Using an internally actuated soft impact, the marker imprints the desired mark onto the workpiece.

- Retract: The marker retracts to its starting position, ready for the next marking operation.

The sequence is initiated either by operator palm buttons or a part-present cycle switch, ensuring safety and precision in automated or semi-automated setups.

Station Details

- Air powered ram

- 4-way valve and air controls

- FRL – Filter Regulator Lock out (OSHA required).

- Holder (or numbering head)

- Fixture mounting plate

- Operator palm buttons (mounting on optional machine base).

- Machine base with caster wheels for mobility