Barstock Marking Machines: Models 2020/4040

Barstock Marking Machines

Columbia Marking Tools' 2- and 4-sided bar stock marking machines are provide super-fast throughput for high volume fittings manufacturers.

This heavy-duty marking system is engineered for high-volume production, capable of marking up to four sides of bar stock with rapid cycle times.

- Model 2020

- Marking 2 sides of hex or round stock or tubes.

- Model 4040

- Marking 4 sides of bex or round stock or tubes.

Barstock Marking Machines

2 and 4 sided Marking Industrial High Production

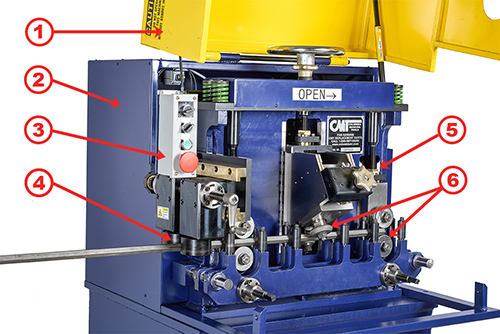

Station Components

CMT Barstock Marking Machine specifications:

- Supports bar stock sizes from 3/8" to 2-1/2"

- Robust, floor-style machine base

- Expanded main machine frame with increased spacing for easier tool change and adjustment

- Heavy-duty Boston drive (10-250 FPM) for continuous operation

- Independent marking pressure rams with self-centering backup support

- Adjustable marking pressure rams with lock-in-place settings

- Forward/reverse variable speed control with "Jog" feature

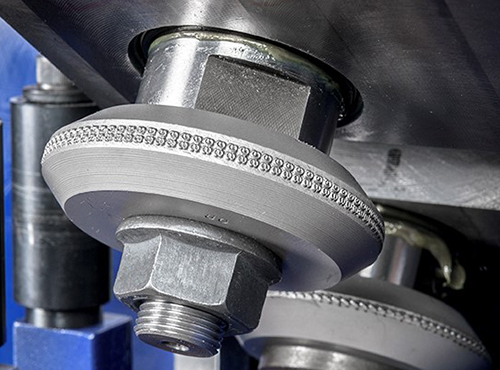

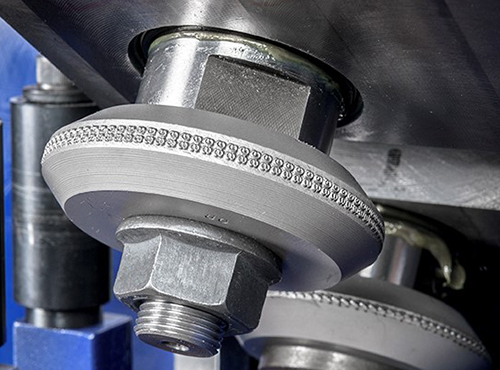

- Heavy-duty Torrington bearings with cast iron housings

- Double-sized "Part Guide" rollers with lever locks

- Safety Features: OSHA-compliant safety guarding with a power disconnect switch

CMT provides complete automation solutions including In-feed loading station for 24/7 lights out operation.

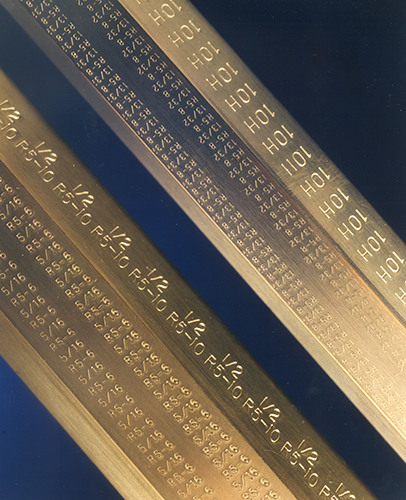

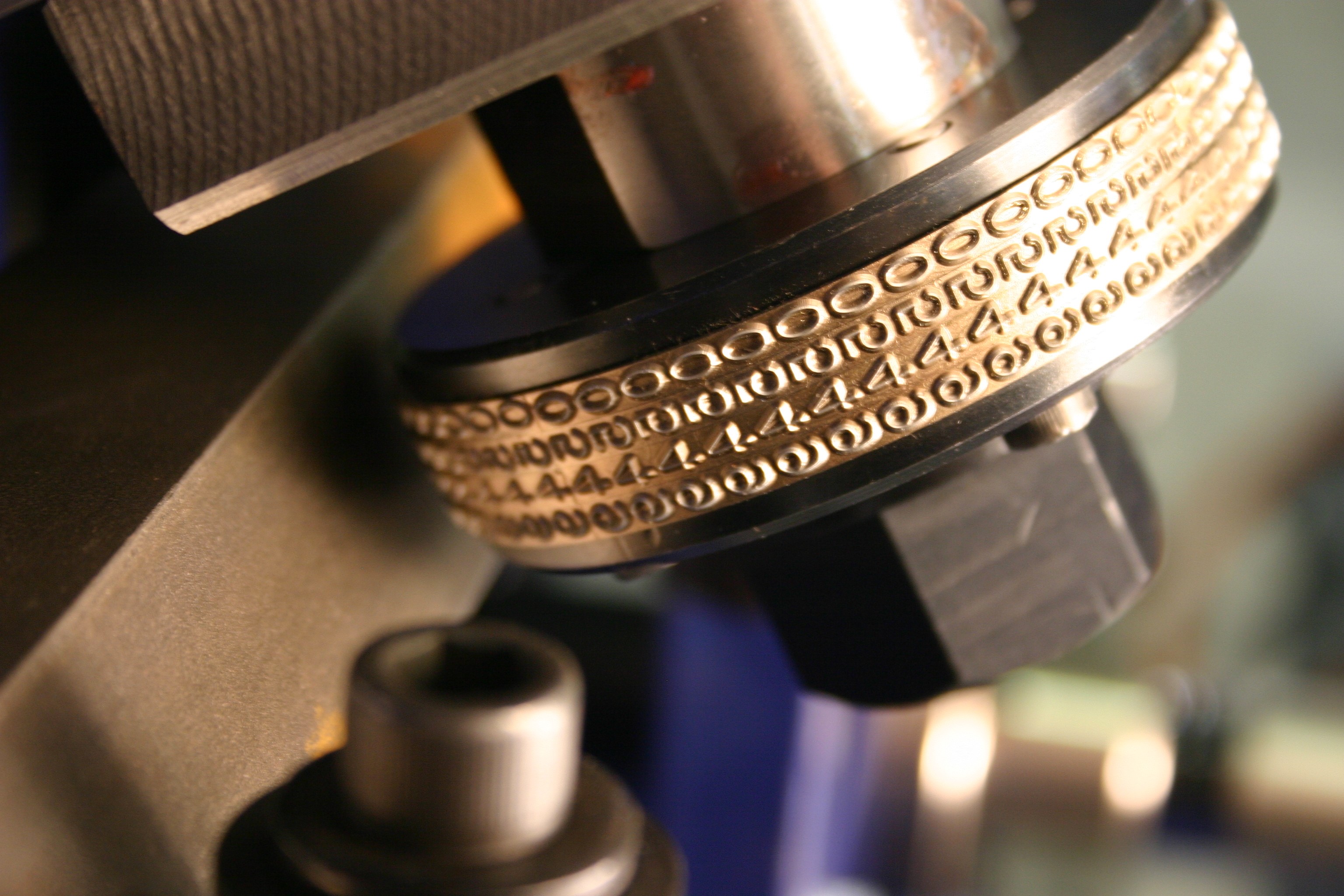

Marking Tooling

Roll marking requires two distinct sets of tooling: Static or Flexible.

Roll Dies - Static

Solid precision engraved dies to provide long lasting durability in the hgih volume marking provided by the model 2020 or 4040.

Wafer Dies - Flexible

Interchangeable wafer dies each with a single figure held in a holder.

Station Details

- Safety Guard Shown Open

- Heavy Duty Frame and Floor Base

- Machine mounted control panel

- In-Feed

- Asjustmet Height - for bar sizes

- Marking Dies (2) sets of (2)

Acessories include: In-feed automation, Roll Dies, Wafer dies and holders.