Hot Stamping Foil Feed

Hot Stamping Comparison

There are two basic styles of CMT hot stamping marks. Hot stamping can create both bold, eye-catching marks and more subtle, understated impressions, depending on whether a contrasting foil is used.

- Marking with contrasting foil =

- This method produces bold, highly visible marks, making it ideal for applications such as logos or part numbers where readability and prominence are key.

- Marking without contrasting foil =

- In this approach, the stamp creates a subtle impression without adding color, perfect for uses like quality control (QC) marks, part tracking, and date codes—areas where the mark needs to be present but not visually dominant.

This versatility makes hot stamping a valuable technique in manufacturing, offering both strong branding and essential, discreet identification.

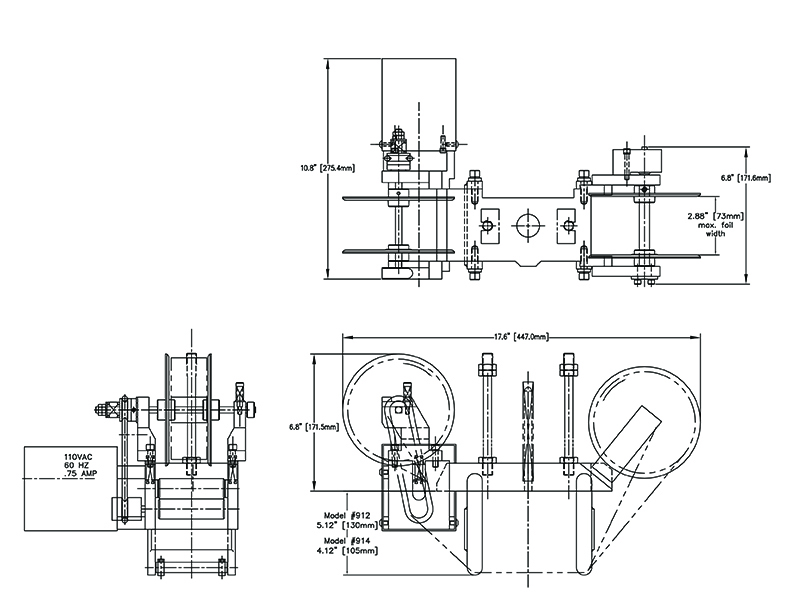

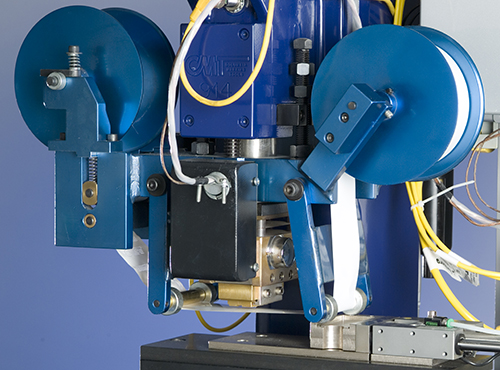

Foil Feed Mechanism and Controls

Our foil feed unit ensures precise, color-embedded impressions by feeding color foil in accurate increments. Key features include:

- Available on Models 914U and 912U

- Accommodates standard 200 ft. rolls in widths ranging from ½” to 2.88” [12.2mm – 73mm]

- Compact Design

- Precise motor advancement

- Integrated controls with temperature.Foil Feed mechanisms require the 900CDHFF controls with the mini-plc.

Hot Stamping Foil

We offer a range of foil widths on 200-foot rolls, available in various colors and metal finishes. Custom formulations are available for specialized applications, including:

- Chemical and abrasion resistnce

- Heavy coverage

- Quick-release proerties