Stamping Dies and Retainers

Columbia Marking Tools Stamping Dies and Retainers

Comprehensive guide for in die part marking.

Production Savings

- Time Savings =

- Combine marking and forming process

- Install Savings =

- Easy milling process to integrate in stamping die

- Cost Savings =

- Inexpensive industry standard available factory direct

Time Savings

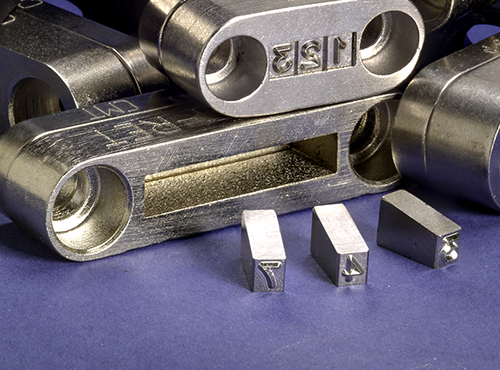

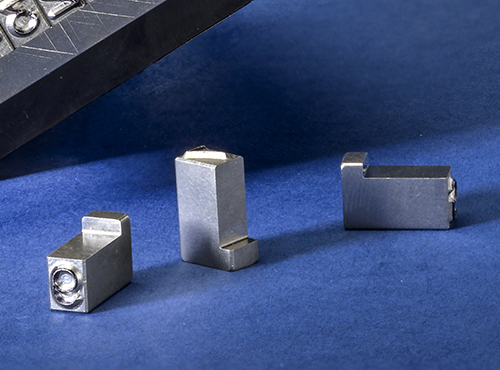

Stamping dies and retainers are critical components in the manufacturing and metalworking industries, particularly in processes like sheet metal stamping. Their design and standardization have enabled manufacturers to quickly and efficiently integrate marking for part traceability directly into the primary stamping process.

By incorporating part traceability, manufacturers can mark or imprint identifying information, such as QC marks, part numbers, or lot numbers, directly onto the stamped part during production. This enhances quality control, enables tracking of parts through the supply chain, and ensures compliance with industry regulations.

Install Savings

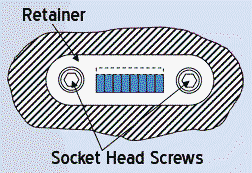

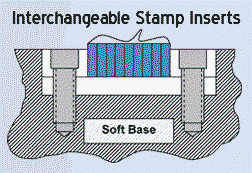

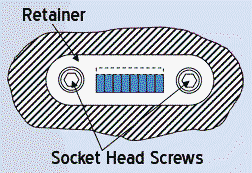

The pocket for the marking retainer and type can be easily milled into an existing die. The width and length of the pocket are determined by the number of characters and the size of each character. Installation of the marking system in the die is done using two socket head cap screws.

Cost Savings

The use of standardized dies and retainers simplifies the setup and implementation of this traceability without disrupting the overall production process. To further reduce maintenance costs, CMT's proprietary manufacturing process extends the tool life of the components, minimizing downtime and reducing overall maintenance expenses. Additionally, the low cost of the dies makes them a cost-effective option for secondary marking processes. CMT also offers a range of adapters and mounting accessories to support diverse applications.

Attachments For secondary marking processes

To provide inventory cost savings CMT has depveoped a complete line of adapters for our Slide-A-Mark air impact marker series. These adapter combine the use of the industry standard type and retainers with the incredible design and function of the compact Slide-A-Mark air impact marker for a secondary process marking option.