Hot Stamping Presses

CMT Hot Stamping Presses

Technical guide to Plastic marking.

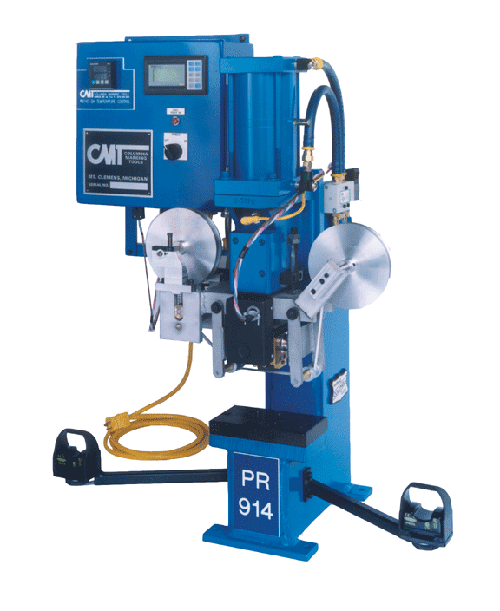

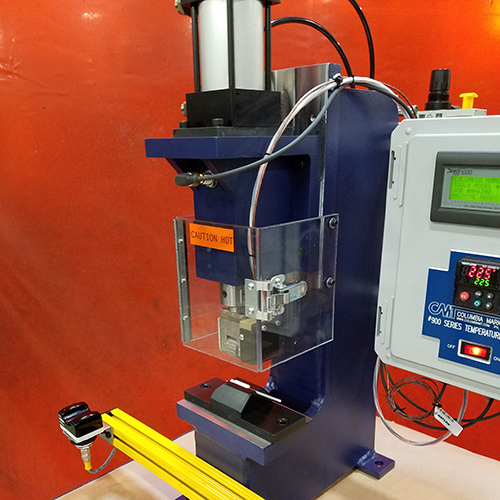

Available in 1/2 ton or 1-ton configurations, the press is fully assembled on an industrial-grade frame with all necessary connections included. Basic safety configuration includes OSHA approved dual palm buttons.

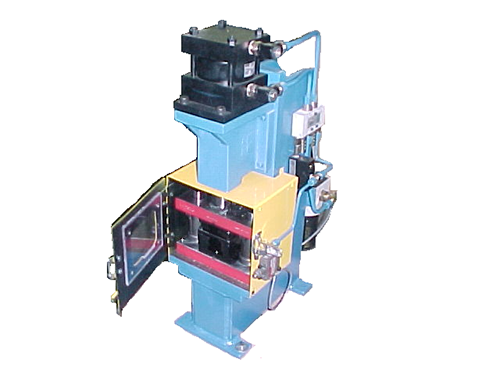

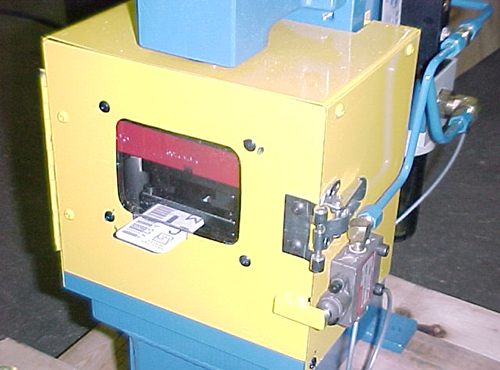

This design may include an upgraded 'part-present' cycle start system. The part is inserted through a small opening in the safety guard, and once it contacts the sensor, the press automatically stamps the required information on the part.

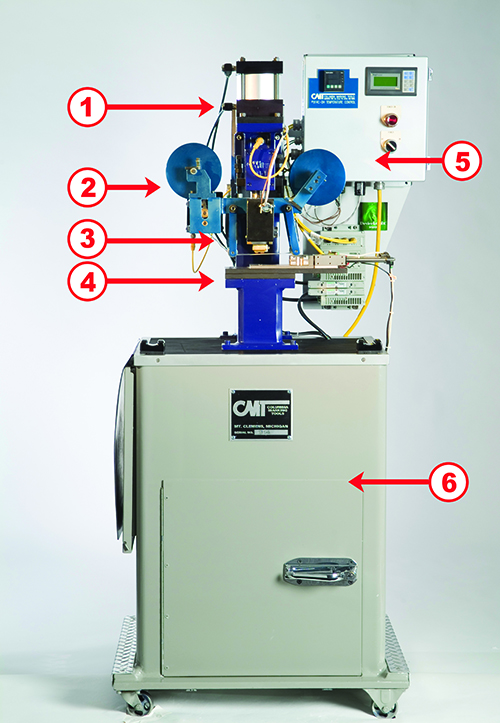

Components of Hot Stamping Press

- 1 Hot Stamping Unit =

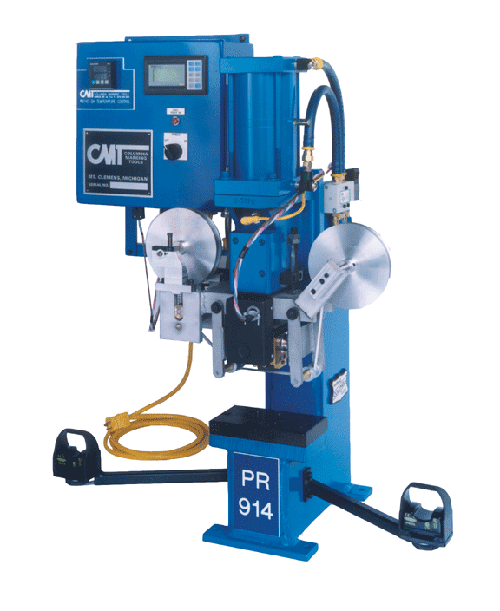

- Selection of Medium – Model 912 or Large – Model 914

- 2 Foil Feed Upgrade =

- Provides contrasting mark and requires PLC upgraded digital heat control.

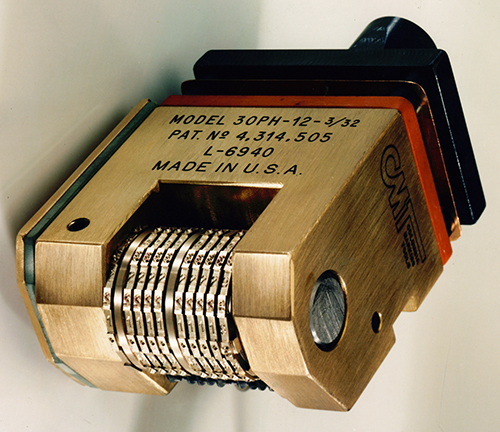

- 3 Tooling =

- Selection includes stamp holder and type, tipping dies, numbering head.

- 4 OSHA required palm buttons =

- May be upgraded to a part present cycle start with guarding.

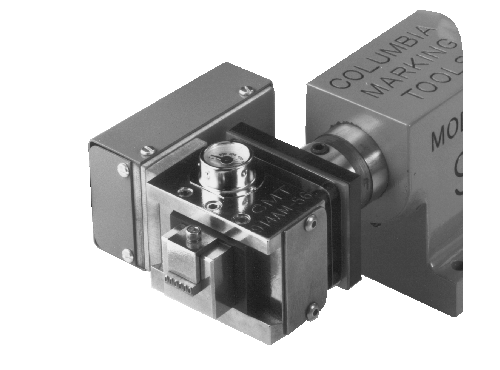

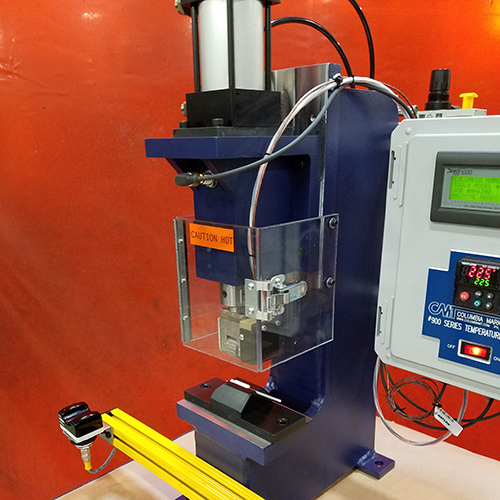

- 5 Digital heat control for J wire thermocouple =

- Shown with PLC upgrade for foil feed system.

- 6 Machine base =

- Heavy duty industrial upgrade.

Hot Stamping Standard Features

CMT hot stamping presses combine all the features of our industrial hot stamping units into a complete station.

Hot Stamping Optonal Upgrades

- Temperature Control Options (with or without Thermocouple)

- Choose between standard temperature settings or enhanced precision control with a thermocouple for more sensitive applications. This allows you to fine-tune heat levels based on specific material or process requirements.

- Hot Stamping Foil (with or without Contrasting Colors)

- Available with or without contrasting hot stamping foil for marking or decorative purposes, enabling flexible customization to suit your design needs and enhance product appearance.

- Heavy-Duty Machine Base for Complete Station (Not Shown)

- A robust, industrial-grade machine base designed to support the entire station, ensuring stability during high-force operations. This sturdy base enhances safety and durability, making it ideal for heavy-duty tasks or environments requiring continuous use.

- OSHA required palm buttons

- May be upgraded to a part present cycle start with guarding.