Model 751/851 - Slide-A-Mark

Slide-A-Mark Advantage

The Columbia Marking Tools SLIDE-A-MARK™ series delivers 6 to 10 tons of marking force with a patented soft-impact air hammer system designed for durability, low noise, and seamless integration into automated production lines.

Key Features:

- Patented Soft-Impact Marking: Minimizes noise and mechanical shock, ideal for delicate assemblies or noise-sensitive environments. This feature allows for the use of external tooling including: holders, numbering head, and anvils and staking tools.

- Telescoping Slide Action: Easily accommodates stamp holders for extended legends and CMT “Select” series numbering heads for randomized machine codes.

- Infinite Rod Orientation: By loosening the rod collar clamp, operators can adjust the radial position of the rod to any angle for maximum flexibility.

- Consistent Marking Depth: The internal air hammer delivers uniform force from 1/2" to the full stroke length, ensuring consistent marks even on parts of varying sizes.

This heavy-duty marker is ideal for mounting into existing automation where space constraints and fixture clearances make standard approaches costly. Its telescoping action eliminates the need for external approach slides, simplifying installation and operation.

CMT Model 751/851 Slide-A-Mark Air Impact Marker

Comprehensive Operation Guide with ordering and maintenance guidelines.

Marking Examples

Product Information

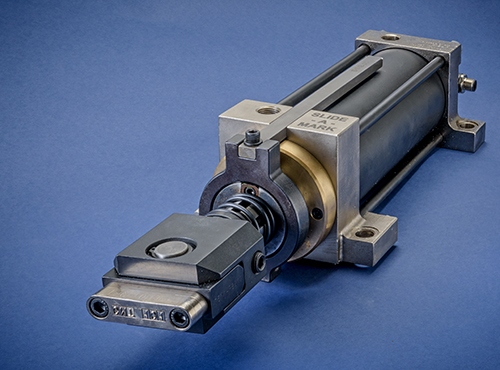

The Columbia Model 751/851 SLide-A-Mark is an impact marking cylinder designed for robust and reliable performance. Here are the key features:

- Design: Air impact markers typically have a straightforward and compact design, making them easy to use and integrate into different industrial settings. The simplicity of their design often translates to reliability and ease of maintenance.

- Durable Marking: The high-impact forces generated by these markers result in durable and long-lasting markings on surfaces. This is particularly important in industrial applications where parts may undergo various stresses, including exposure to harsh environmental conditions.

- Speed and Efficiency: Air impact markers are known for their speed and efficiency in marking parts. This is crucial in industrial production processes where rapid and accurate marking is essential for maintaining a smooth workflow and high productivity.

- Versatility: These markers can be used on a wide range of materials, including metals, plastics, and composites. This versatility makes them suitable for diverse industrial applications.

- Integration with Automation: The compact design of air impact markers allows for easy integration into both manual and automated production processes. This adaptability is valuable for industries seeking efficient and automated solutions to streamline their production lines.

- Low Maintenance: The robust and simple design of air impact markers often results in low maintenance requirements. This can contribute to cost savings and reduce downtime in industrial settings.

- Consistent Marking QUality: The model offers 2.5 to 6” inches of stroke, providing versatility for different marking requirements.

- Adjustable Settings: Many air impact markers come with adjustable settings, allowing users to control the force and depth of the marking. This flexibility is useful when working with different materials and applications.

- Integrated Advance and Return Sensor: CMT offers integrated sensor option to signal that the marker has both advanced and returned positions.

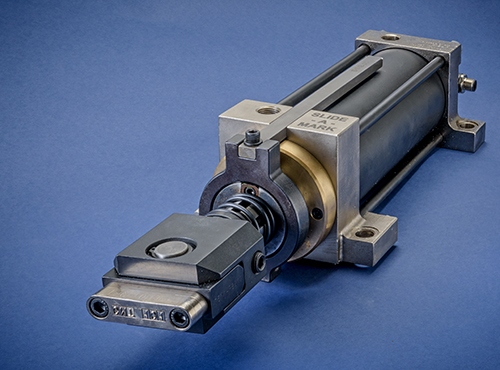

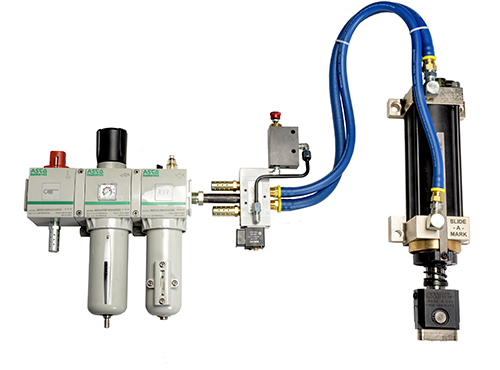

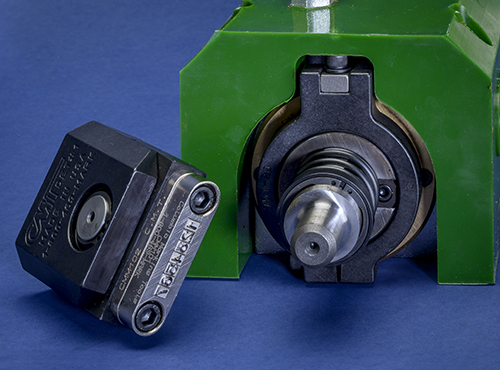

Shown with most popular configuration; K style rod and holder, 2 1/2" stroke, and standard lubricated compressed air supply.

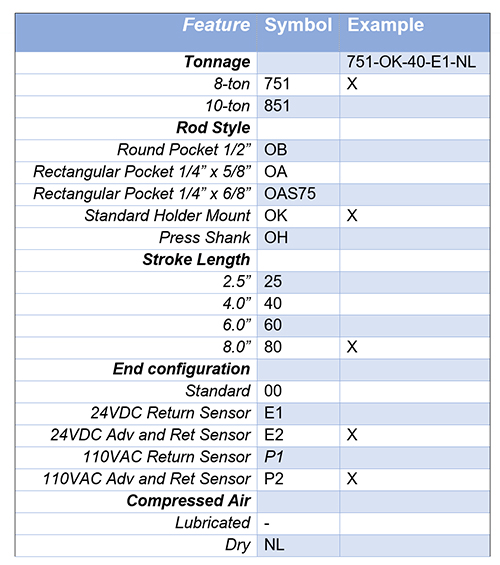

- Rod Styles =

- Muti-character OA for CMG groove type

- Muti-character OAS75 for CMG groove type

- Single character OB for CM9X round insert

- Holder OK - Ball lock

- Holder OH - Press shank mount

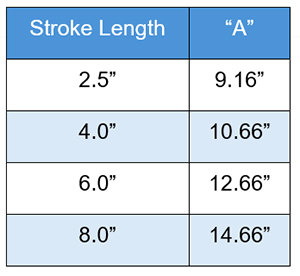

- Stroke Lengths =

- 2.5"

- 4.0"

- 6.0"

- 8.0"

- End configurations =

- Standard

- E1 - 24VDC Return Sensor

- P1 - 110VDC Return Sensor

- E2 - 24VDC Return and Advance Sensor

- P2 - 110VDC Return and Advance Sensor

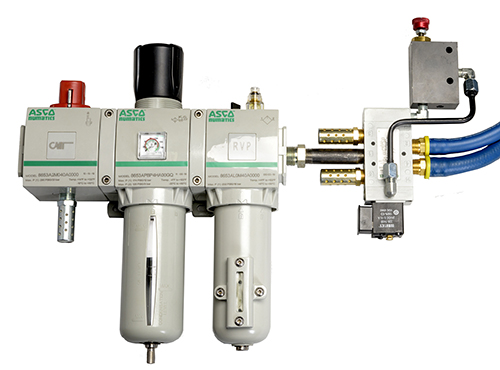

- Compressed Air =

- Lubricated

- Dry

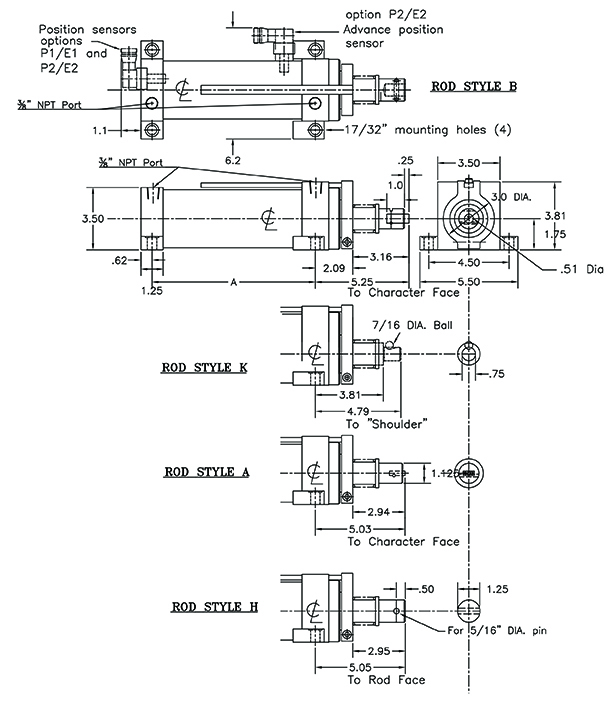

- Stamp Capacities Rod Style “B” =

- (1) Pc CM9X round insert can mark up to a 3/8"” character.

- Stamp Capacities Rod Style “A” =

- (10) Pc’s 1/16” Char. of CMG06 Stamp Inserts. (5) Pc’s 1/8” Char. of CMG13 Stamp Inserts

- Stamp Capacities Rod Style “AS75” =

- (12) Pc’s 1/16” Char. of CMG06 Stamp Inserts. (6) Pc’s 1/8” Char. of CMG13 Stamp Inserts

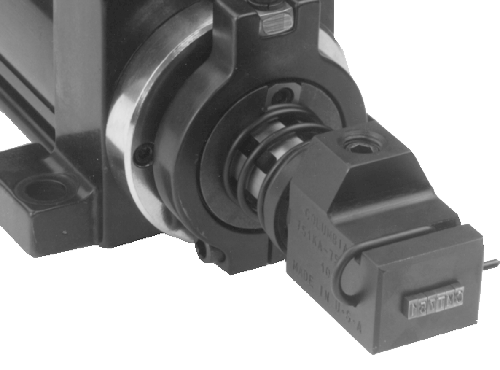

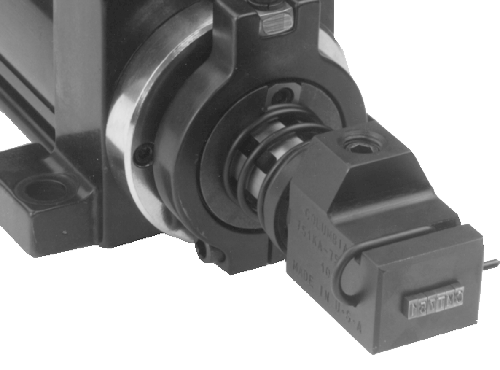

The Slide-A-Mark has a “soft” impact and can use external tooling. Two standard tooling options:

- "K" =

- Ball lock mount is designed for use with a ball and set screw retention method to keep the ball seated in the tool mount.

- "H" =

- Press shank mount for tooling operations with extreme vibrations and application force.

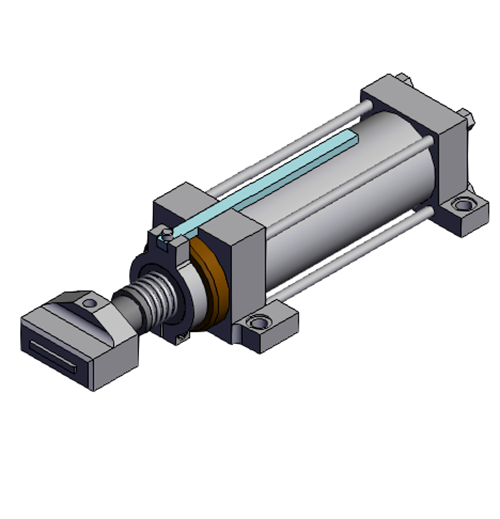

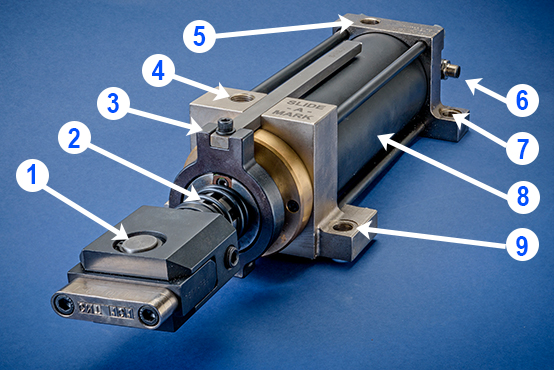

Model 751 K style rod

- Holder & Type - optional tooling used with ball lock rod style K

- Compression sprng

- Collar and guide rod

- Return air port

- Advance air port

- Optional upgrade - return position sensor

- Rear cap and mounting holes

- Sleeve

- Front cap and mounting holes

Technical Details

Select options from the chart to build the complete part number.

Selections:

The force selection should be based on the total force required to mark the entire mark.

Stroke length provides the reach for the Slide-A-Mark to connect with the part. While at the same time assuring the tooling is out of the way of any part handling.

The E2 option provides a position sensor in both the advance and retract positions. The advance sensor may be slightly adjusted to accommodate the part position. WARNING – the Slide-A-Mark does not have to extended to the full length of stroke to mark the part – the E2 option is not viable when marking parts of different sizes.

The size of the model 751/851 varies with the stroke of marker. The addditional stroke length will allow the marker to reach farther to the workpieces, while at the same time extend the length of the impact marker sleeve.