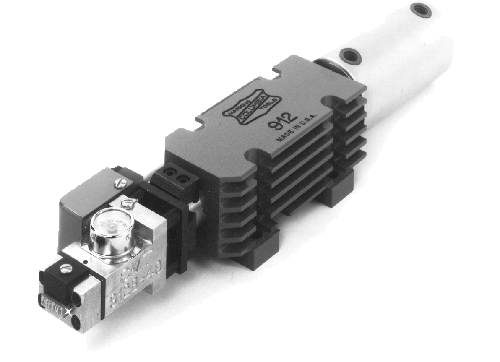

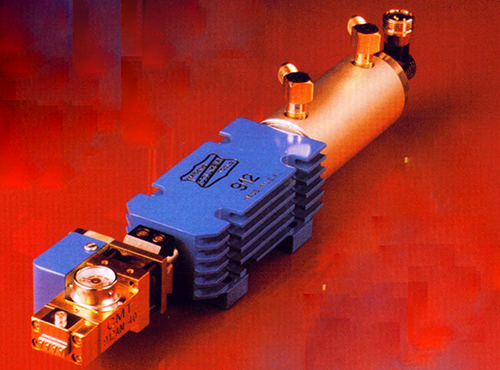

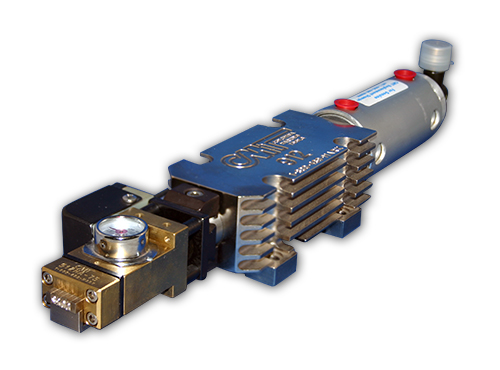

Hot Stamping Unit Medium - Model 912

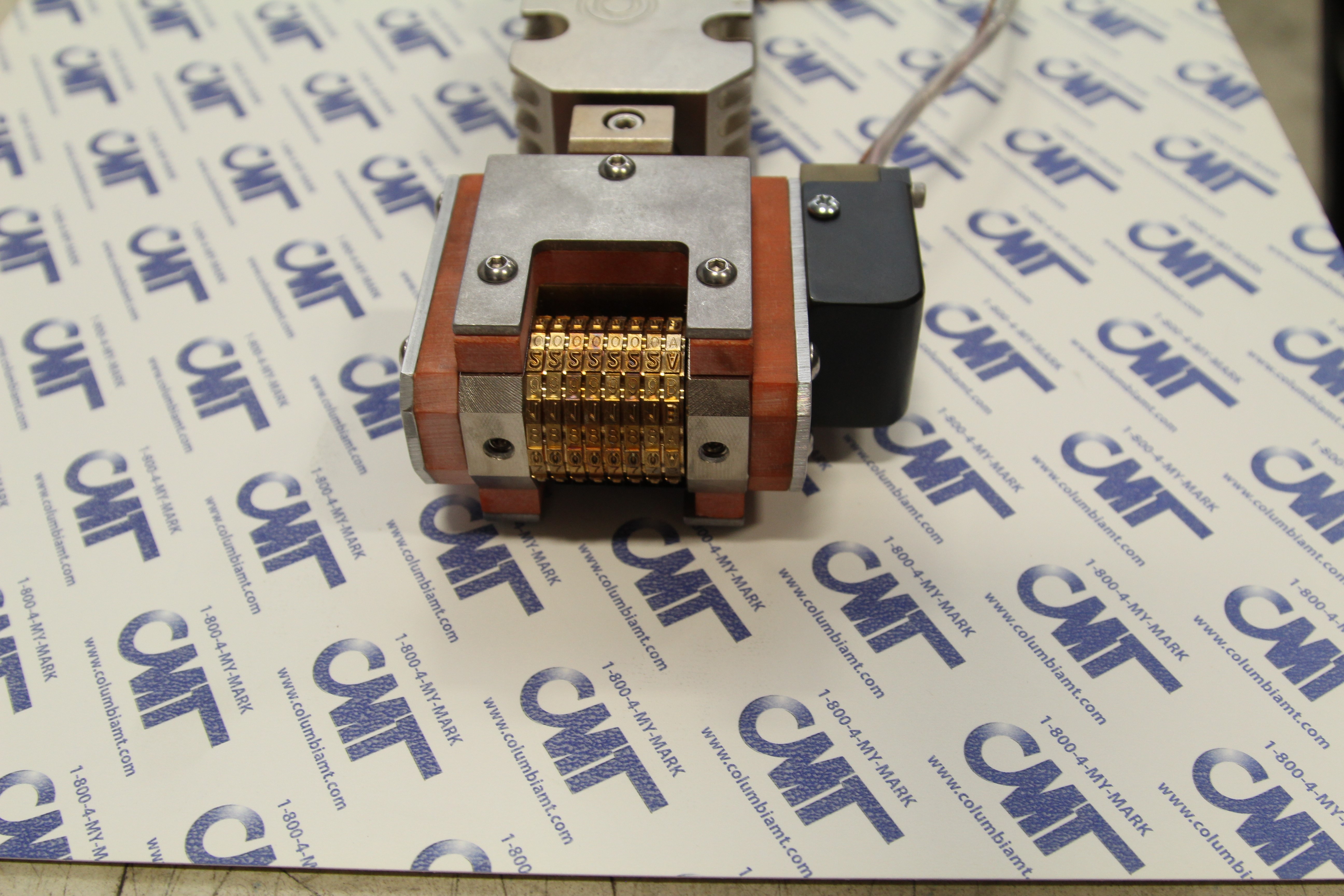

The Model 912 hot stamping unit from Columbia Marking Tools stands out as one of the most popular and versatile choices for part traceability. With its robust force and size, it accommodates a wide range of marking needs, from part numbers to date codes. The unit offers flexibility through optional features like a numbering head, which enables automated serial numbering, making it an efficient and reliable tool for diverse industrial marking applications.

Versatile Hot Stamping Unit

Technical guide to Model 912.

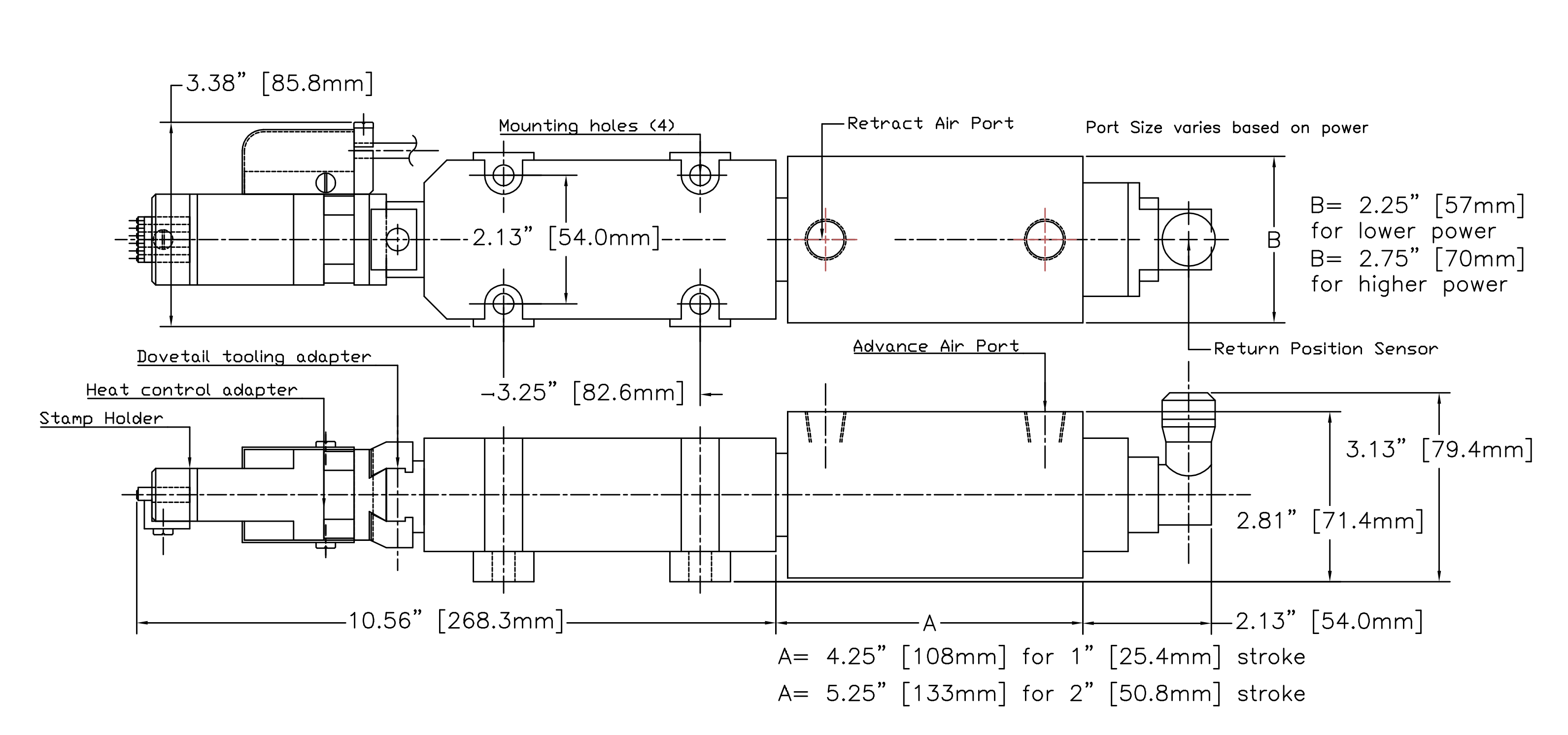

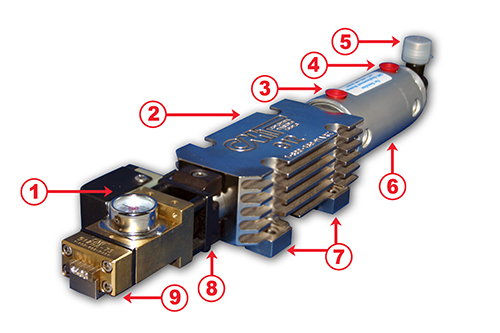

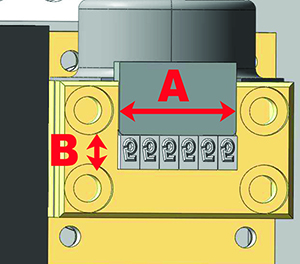

- Heat control adapter - Temswitch or J Wire Thermocouple

- 912 Body Heat dispersion

- Retract air port

- Advance air port

- Retract position sensor - optional

- Air cylinder - 2 power options, and 2 stroke options

- Mounting locations (4)

- Dovetail mount for heat control or tooling

- Stamp holder and type - sold separately

Technical Specifications

- Maximum Marking Force – 360 lbs [163 kgf]

- Operating Pressure – 20-80 psi [1.4-5.5 bar]

- Maximum Temperature - 350 [°F [177 °C]

- Dwell Time (suggested) 0 to 5 seconds

- Electrical Requirements – 120 Vac

- Air Requirements – compressed lubricated air

Air Connections

- 1/4-NPT Advance and Retract air ports for low power range

- 3/8-NT Advance and Retract air ports for High power range

- Suggested Pnuematic Controls

Electrical Connections

- Midget twist lock (hubbell 7594) provided with M or J options. (3) foot cable inlcuded.

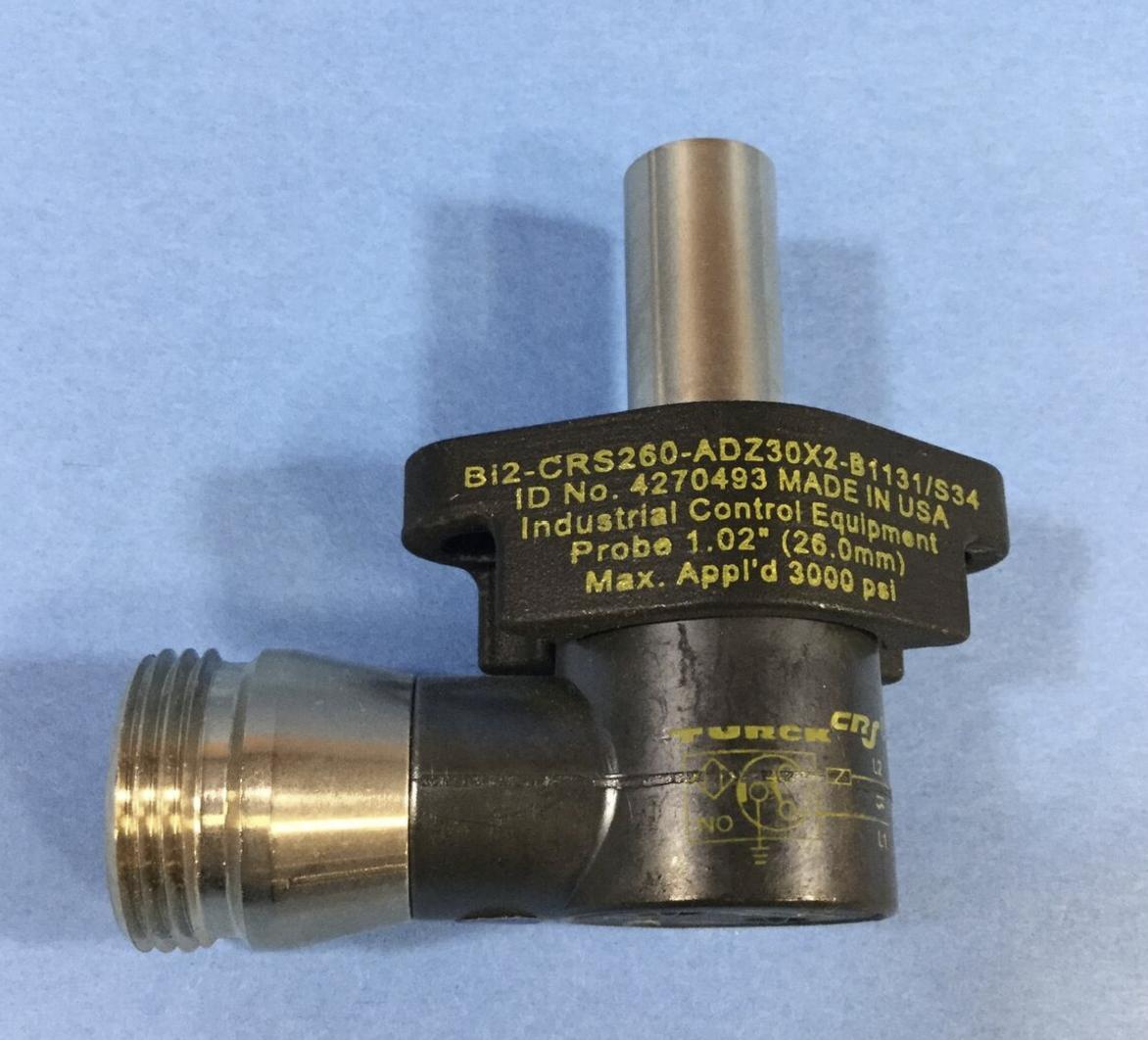

- Return position sensor (optional). Cable sold separately.

- Thermocouple J wire connection with only opton j. (3) foot of cable included.

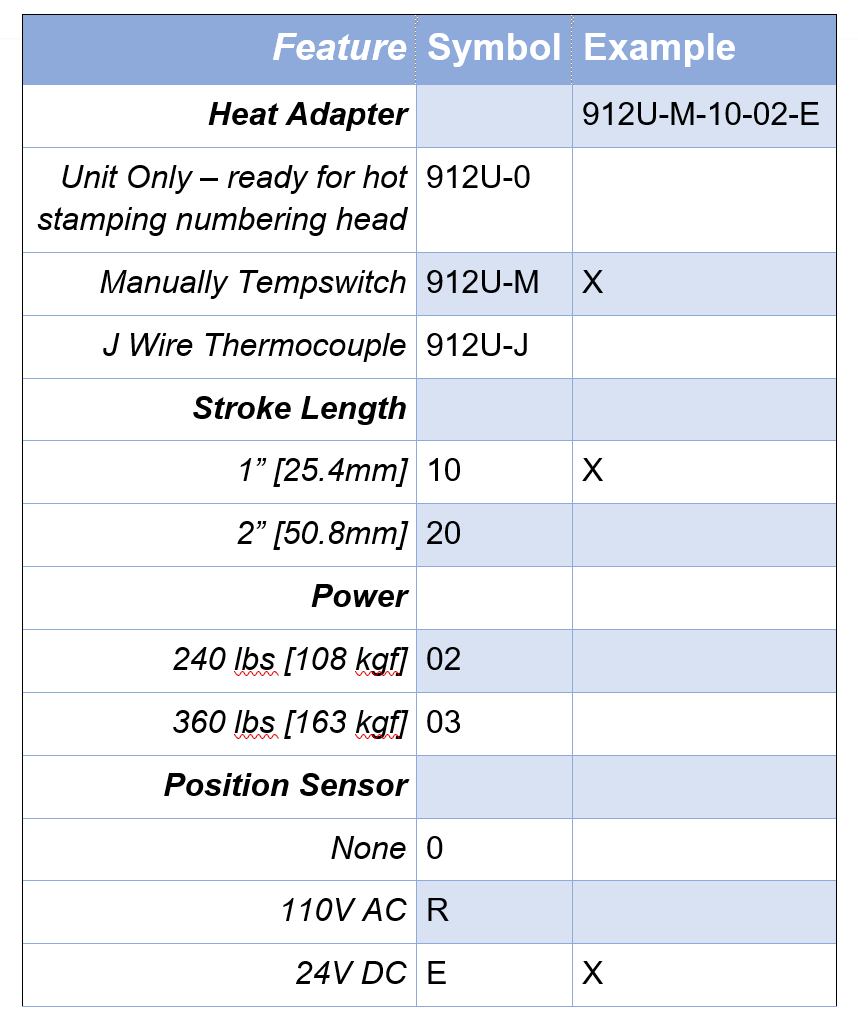

Selections

- Heat control - Manual or Digital

- Stroke length

- Power -Low or High

- Return position sensor

Heat Contol

The heat cotrol may be purchased with the unit or separately. Connection cables are provided with the heat control if required.

- Manual - 912AM40 - Manually adusted tempswitch

- Automatic - 912AJ40 - Automatically controlled J wire thermocouple

Notes

- Port sizes vary based on the power of the unit

- The size of the unit varies with both the power and the stroke length

- Drawings for standard designs are provide with the quotation upon request.

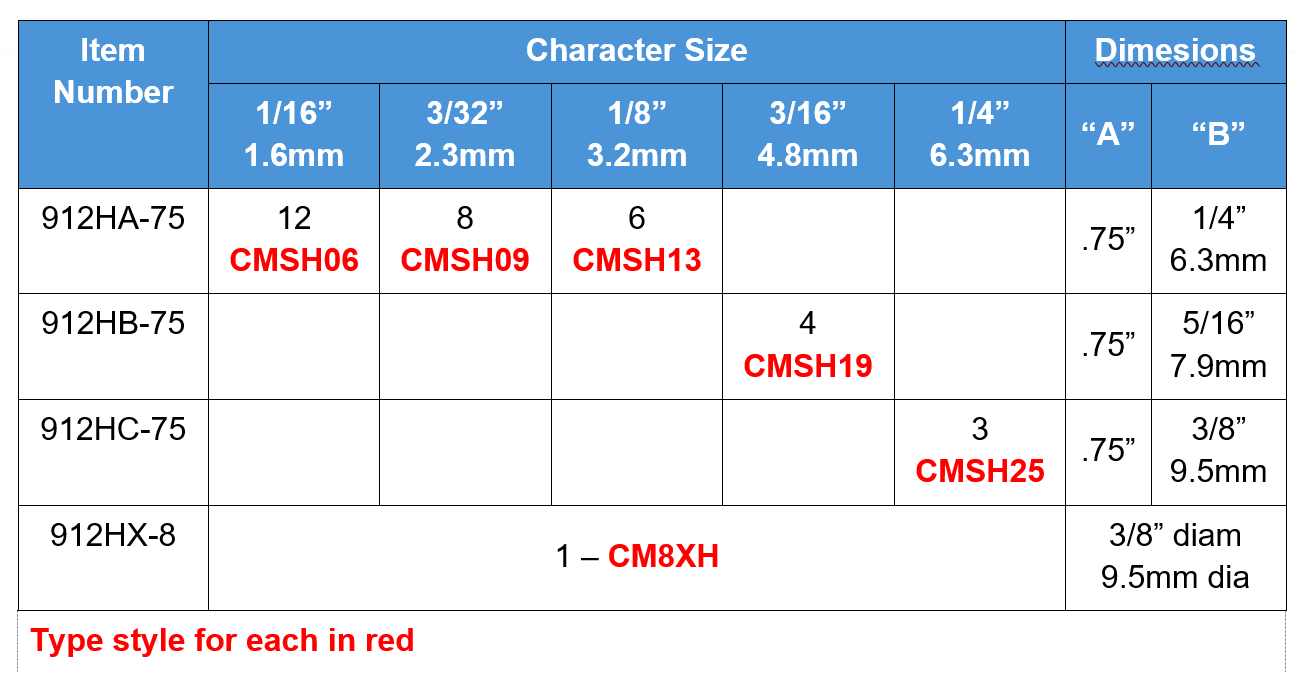

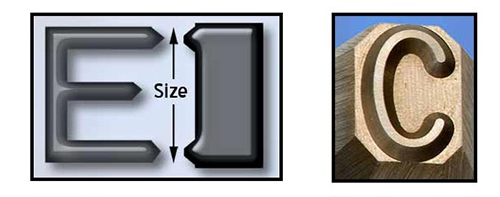

Standard CMSH Step Type are engraved as flat face characters. The wide face of the character allows for easy ransfer of heat.

Option R - Mini

- Largest available (7/8" x 16 thread)

- 20 volt/ 250 volt

- AC or DC

- 3 pin, 2 wire, normally open (+/- can be switched)

Option E - Eurofast

- Small metric (M12 x 1 thread)

- 10 volt/ 65 volt DC

- 4 pin, 3 wire, normally open (+, pnp sourcing)

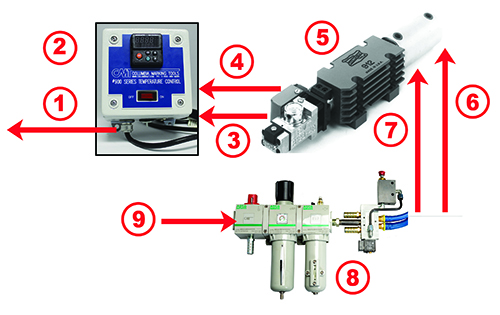

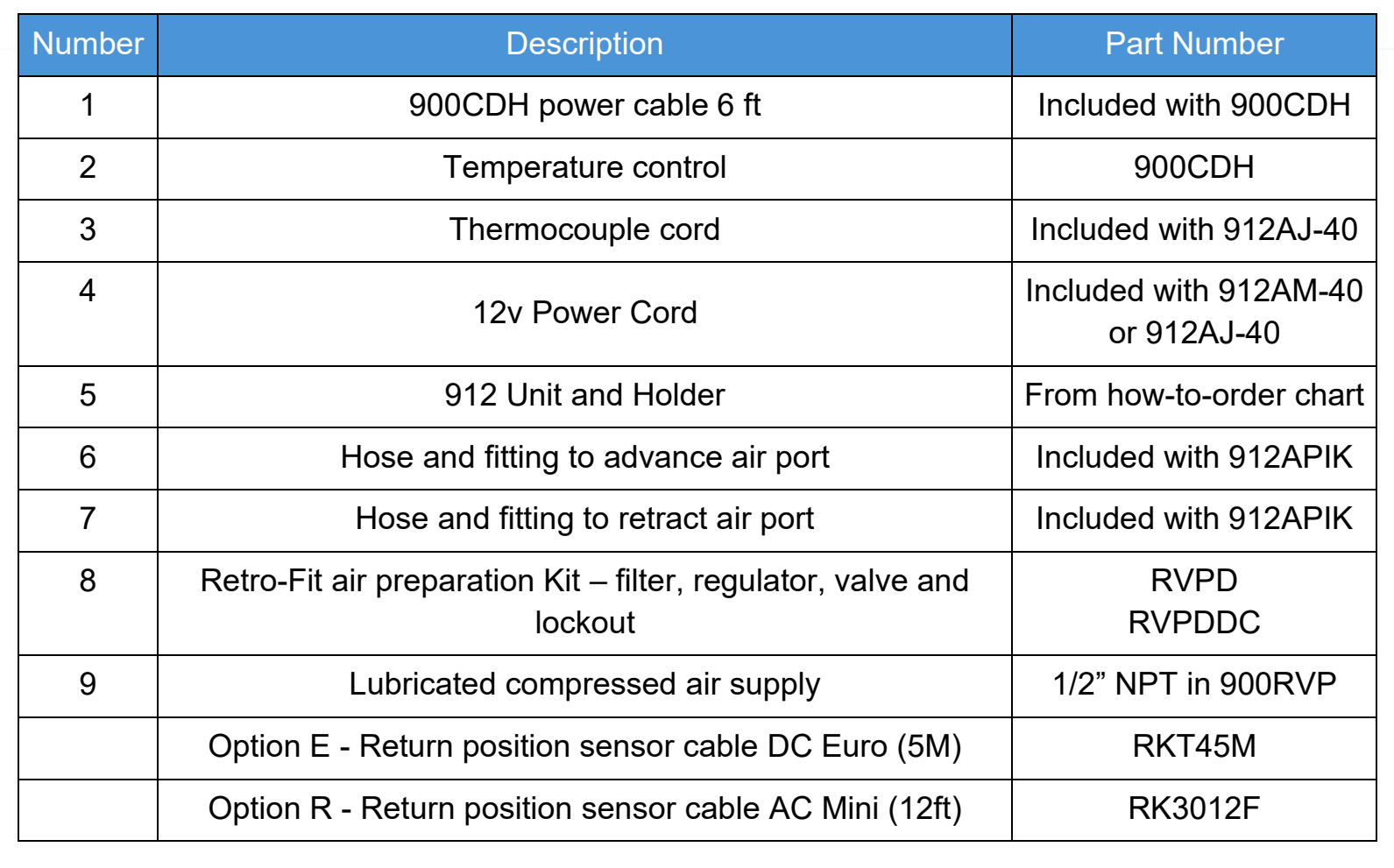

The CMT model 912 hot stamping unit may be integrated inline for production traceability marking of industrial products. The unit may be purchased by itself, or CMT offers a wide selection of accessories.

CMT offers complete air preparation kits and valve packs – connects to 6 & 7.

Part #912APIK contains all the required fittings and hoses for installation.

Part #RVPD or RVPDDC includes filter, regulator, valve and OSHA required lockout.