Roll Marking Concept

Roll Marking Concept

Basic Roll Marking: For roll marking, the mark is "rolled" onto the part. It is an ecomonic solution in applications where tonnage requirements make a press too costly. It is also a pratical method where fragile parts would be damaged by stamping pressure. This method can be used on both flat and round parts.

![]()

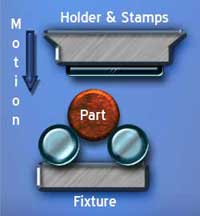

Step #1: |

Part in position to be marked. May require part locating fixture or roll cradle as shown. |

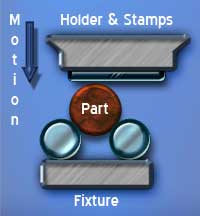

Step #2:  |

Marking die approaches and contacts part. Columbia Marking Tools' "Seek & Find" pressure system assures constant marking pressure on the part at all times. |

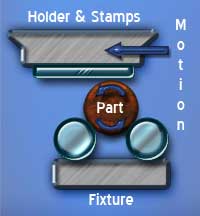

Step #3:  |

Marking die moves accross part. Approximately one character is in contact with the surface of the part at any time. Round part rolls with die in roll cradle. |

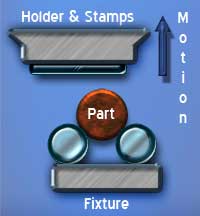

Step #4:  |

After moving the length of the slide stroke the roll marking die retracts from the part. |

![]()

For all Columbia roll marking machines we suggest using quality Columbia Marking Tools dies and inserts:

- Individual type

- Segment type with multiple characters - company logos and special symbols

- Timing marks

- Roll dies with designs (knurling)

- Roll marking numbering dies